Ken Moore

Lifetime Supporting Member

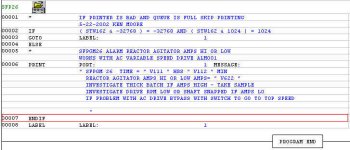

Hi folks, I have an older TI565 w/128k memory card, that is reaching its limits. (Everything except PLC base is 505 hardware vs 500) We have had to play with loop and SFPGM timing to prevent excessive overruns. Scan time is around 200-250msec.

Around 2 years ago we approached Siemens about upgrading, after all the migrate to S7 hype, we finally got a recommendation. Move up to the 555-1105. We then asked if our program would migrate without any changes, and could we still use our Quickbasic batching system (uses task codes to pass data to plc), we got a blank stare and a maybe answer. We emailed a copy of our program to Siemens so they could check it out for compatibility issues. Never heard anything back. Kept calling , but always got the "we're working on it" answer. I believe they just ignored us since we refused to go with S7. So we dropped the upgrade.

Now we are finding 565 parts harder to locate and we may need to expand the system sometime soon. So we are once again looking to upgrade the processor. Has anyone done something similar, where there any compatibility issues. My main concerns are with SFPGM's (we are currently running 228 of them) and the task codes.I have a copy of the 575 task codes,and they appear to be the same as the 565. I'm hoping nothing major has changed over the years.

Any and all comments will be greatly appreciated.

Ken

Around 2 years ago we approached Siemens about upgrading, after all the migrate to S7 hype, we finally got a recommendation. Move up to the 555-1105. We then asked if our program would migrate without any changes, and could we still use our Quickbasic batching system (uses task codes to pass data to plc), we got a blank stare and a maybe answer. We emailed a copy of our program to Siemens so they could check it out for compatibility issues. Never heard anything back. Kept calling , but always got the "we're working on it" answer. I believe they just ignored us since we refused to go with S7. So we dropped the upgrade.

Now we are finding 565 parts harder to locate and we may need to expand the system sometime soon. So we are once again looking to upgrade the processor. Has anyone done something similar, where there any compatibility issues. My main concerns are with SFPGM's (we are currently running 228 of them) and the task codes.I have a copy of the 575 task codes,and they appear to be the same as the 565. I'm hoping nothing major has changed over the years.

Any and all comments will be greatly appreciated.

Ken