Scubasteve2365

Member

Hello,

I'm using the PIDE instruction for the first time. While it's not my first time tuning a PID, most of the other times in the past has been done with a PID instruction and I've just used simple tuning methods to dial it without becoming an "expert" at each of the terms.

For this project, a new facility and installation, I've using View distributed and am content with the process graphics library. The faceplates in that library utilize the PIDE instruction.

From what I gather, the difference here being a velocity versus position sort of calculation.

I have several different loops, some temperature control, others flow control, level control ect throughout this facility. I am still working on tuning of course, but I've noticed behavior that I have not noticed before.

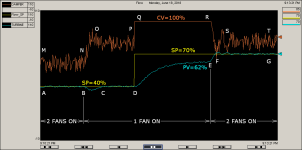

Let's say I have a temperature that I am trying to regulated with chilled water through a control valve. At times, I've the CV has been at 0% or 100% The limits I've set) for a period of time, when the PV overshoots the CV will hang for what I believe is quite awhile (i.e., chilled water valve remaining 100% open when temperature overshoots to being under setpoint) sometimes for upwards of 1 minute before the CV starts responding to correct in the other direction.

All deadzone features are disabled or at 0.

I did some searching (here and google) before posting and I read some comments that referred to integral windup, wherein the i-term will continue to accumulate even though the CV is clamped. Which then means the accumulation would have to work it's way back down before the CV would change. It wasn't clear that if this applied to the PIDE instruction, because other comments/info I read indicates that i-term will stop accumulated once CV min/max is established.

Also, the i-term itself (for independent) are 1/sec for PID, and 1/min for PIDE. It's unclear to me if my i-term would be 60 times larger (sec to min) or 60 times smaller (min to sec) compared to a PID. It's likely that my i-term is set incorrectly.

For example, a loop that I am happy with at another facility using a PID instruction is kp=2, ki= 0.1, and kd = 0). Assuming all else being equal, if I

wanted to bring that into the PIDE instruction, would the ki need to be 6?

Sorry for the wall of text, appreciate any feedback.

I'm using the PIDE instruction for the first time. While it's not my first time tuning a PID, most of the other times in the past has been done with a PID instruction and I've just used simple tuning methods to dial it without becoming an "expert" at each of the terms.

For this project, a new facility and installation, I've using View distributed and am content with the process graphics library. The faceplates in that library utilize the PIDE instruction.

From what I gather, the difference here being a velocity versus position sort of calculation.

I have several different loops, some temperature control, others flow control, level control ect throughout this facility. I am still working on tuning of course, but I've noticed behavior that I have not noticed before.

Let's say I have a temperature that I am trying to regulated with chilled water through a control valve. At times, I've the CV has been at 0% or 100% The limits I've set) for a period of time, when the PV overshoots the CV will hang for what I believe is quite awhile (i.e., chilled water valve remaining 100% open when temperature overshoots to being under setpoint) sometimes for upwards of 1 minute before the CV starts responding to correct in the other direction.

All deadzone features are disabled or at 0.

I did some searching (here and google) before posting and I read some comments that referred to integral windup, wherein the i-term will continue to accumulate even though the CV is clamped. Which then means the accumulation would have to work it's way back down before the CV would change. It wasn't clear that if this applied to the PIDE instruction, because other comments/info I read indicates that i-term will stop accumulated once CV min/max is established.

Also, the i-term itself (for independent) are 1/sec for PID, and 1/min for PIDE. It's unclear to me if my i-term would be 60 times larger (sec to min) or 60 times smaller (min to sec) compared to a PID. It's likely that my i-term is set incorrectly.

For example, a loop that I am happy with at another facility using a PID instruction is kp=2, ki= 0.1, and kd = 0). Assuming all else being equal, if I

wanted to bring that into the PIDE instruction, would the ki need to be 6?

Sorry for the wall of text, appreciate any feedback.