Hi good people

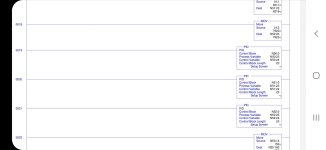

I have a question regarding a program on a machines heater control, I have 3 x heater contactor controlled via a plc

It looks like the contactor is controlled via timers rather then the pid in the program?

Can you explain why pid is not being used full and the timers energize the output to the contactor, could it gave been done with the output of the pid ?

I have a question regarding a program on a machines heater control, I have 3 x heater contactor controlled via a plc

It looks like the contactor is controlled via timers rather then the pid in the program?

Can you explain why pid is not being used full and the timers energize the output to the contactor, could it gave been done with the output of the pid ?