You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

OT: Descriptive Tag Names

- Thread starter ASF

- Start date

seth350

Member

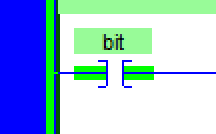

I mean...it is a bit though? Right?

So it’s not the most least descriptive.

I said that with sarcasm. Lol

Change the name to “whatamI”

So it’s not the most least descriptive.

I said that with sarcasm. Lol

Change the name to “whatamI”

BryanG

Member

I don't think it is the descriptive names they are having trouble with, just grammar. Then it is easy, that contact closes when something has been bitten.

cardosocea

Member

I think you are being a bit harsh (no pun intended)...

It is actually very descriptive, the problem is that it's describing what it is and not what it does.

This is quite likely not the case here, but I was in a position once to be working for a really dodgy company without a signed formal contract in place (I know, not ideal, but didn't really had lots of choices) and all variables created were inside arrays. I had an array of int, unsigned int, float, char, etc...

This was all in C, so I had actual description for each bit in a separate file as a bunch of #define instructions.

At the end of the project, I spent a bit of time replacing all of these #defines by the corresponding number and handed them those files as source code. Fully functioning, some comments (not even close to what I consider standard), no compilation warnings, etc...

Obviously, well before they even looked at the code the payment bounced because they didn't make profit off of the project (which I can understand considering how clueless they were on how markets work)... a couple of months later I get a call from the guy saying the code was unreadable and I needed to fix it or give him the real source code. I just pointed to the missing payment and the fact that if it was indeed a loss for the company they wouldn't be using the code either way and he should test things before making claims that it isn't the real code as it is indeed the correct software.

I'm pretty sure he just got another out of Uni guy to basically re-write the whole thing instead of paying (what I now realise) was peanuts.

Not saying that is the case here... but sometimes it's a way to get your money.

It is actually very descriptive, the problem is that it's describing what it is and not what it does.

This is quite likely not the case here, but I was in a position once to be working for a really dodgy company without a signed formal contract in place (I know, not ideal, but didn't really had lots of choices) and all variables created were inside arrays. I had an array of int, unsigned int, float, char, etc...

This was all in C, so I had actual description for each bit in a separate file as a bunch of #define instructions.

At the end of the project, I spent a bit of time replacing all of these #defines by the corresponding number and handed them those files as source code. Fully functioning, some comments (not even close to what I consider standard), no compilation warnings, etc...

Obviously, well before they even looked at the code the payment bounced because they didn't make profit off of the project (which I can understand considering how clueless they were on how markets work)... a couple of months later I get a call from the guy saying the code was unreadable and I needed to fix it or give him the real source code. I just pointed to the missing payment and the fact that if it was indeed a loss for the company they wouldn't be using the code either way and he should test things before making claims that it isn't the real code as it is indeed the correct software.

I'm pretty sure he just got another out of Uni guy to basically re-write the whole thing instead of paying (what I now realise) was peanuts.

Not saying that is the case here... but sometimes it's a way to get your money.

AustralIan

Member

Was the rest of the rung like this, completing the famous proverb?

Code:

BIT ONS.1 ONS.2 SHY

-][-+--][----[ONS]-------+-()

| ONS.0 ONS.1 ONS.0 |

+--][----[ONS]--]/[--+

| ONS.0 |

+-[ONS]--------------+Saffa

Member

I feel your pain. I have just inherited a project from a colleague that was an SLC500 to Schneider M340 conversion. Schneider do a reasonable job of auto converting your original .RSS but of course all new variables are named as per the old file numbers i.e. N9_55. The idea is that you can swap out hardware and be back up and running in a short period of time. That was the case, i rewired the panel he put in the code, back up in full auto in 2 days.

Now Unity Pro is awful for Ladder... FBD is a lot better. I had assumed he would spend the next 2 weeks slowly moving over chunks of code to FBD, using our standard library blocks where possible, and all the new plant additions that dictated the upgrade would be done with meaningful tags.

Nope.

New tags were created that followed the N9_55 naming convention even though it was now meaningless. New logic now interspersed within the old logic instead of in new sections. Even reused the custom blocks that Schneider made to emulate the old SLC functions like SCP, TON etc instead of using the Unity style ones.

When i asked him what he was thinking he really couldn't see what was wrong.

Now Unity Pro is awful for Ladder... FBD is a lot better. I had assumed he would spend the next 2 weeks slowly moving over chunks of code to FBD, using our standard library blocks where possible, and all the new plant additions that dictated the upgrade would be done with meaningful tags.

Nope.

New tags were created that followed the N9_55 naming convention even though it was now meaningless. New logic now interspersed within the old logic instead of in new sections. Even reused the custom blocks that Schneider made to emulate the old SLC functions like SCP, TON etc instead of using the Unity style ones.

When i asked him what he was thinking he really couldn't see what was wrong.

cardosocea

Member

I feel your pain. I have just inherited a project from a colleague that was an SLC500 to Schneider M340 conversion. Schneider do a reasonable job of auto converting your original .RSS but of course all new variables are named as per the old file numbers i.e. N9_55. The idea is that you can swap out hardware and be back up and running in a short period of time. That was the case, i rewired the panel he put in the code, back up in full auto in 2 days.

I have the same on a Rockwell to Siemens conversion... needless to say we're not paying for the software on any further conversions and will just do this ourselves as it will take much less time.

KB1GNI

Member

Back when I first started working with PLCs I remember a program that had a bit labeled "Who know what this thing do".

Not sure I ever figured it out, either...

Not sure I ever figured it out, either...

Ronnie Sullivan

Member

I wrote on here about the one I saw.

It was labelled 'I was tricked '

I eventually worked it out that it was a false trigger of a photo cell.

It was labelled 'I was tricked '

I eventually worked it out that it was a false trigger of a photo cell.

John Morris

Lifetime Supporting Member

In Idec using the counter it has thee inputs, trigger, pulse, and a bit to hold it high or low for up count or down count.

I always labeled it "Doesn't do a dam thing".

I always labeled it "Doesn't do a dam thing".

janner_10

Lifetime Supporting Member

From a customer of ours in the states, just why?

Was the rest of the rung like this, completing the famous proverb?

Code:BIT ONS.1 ONS.2 SHY -][-+--][----[ONS]-------+-() | ONS.0 ONS.1 ONS.0 | +--][----[ONS]--]/[--+ | ONS.0 | +-[ONS]--------------+

It was not, but next time I'm on site I'm putting that rung in

seth350

Member

What about buffering a float to 20 different F8_## tags in a converted 500 program?

I can’t stand to see converted programs not gone through and given descriptive tag names.

I think those are the most least descriptive and lazy.

OEMs, I’m looking at you.

Rockwell was actually going to do this for us for a program in a modernization project. Went through explaining how the program would be converted and tested by their engineers and how great it would be.

Me: “Are you going to rename the tags to descriptive names?”

Rockwell: “No...”

Me: “So what service are you offering again? I thought we were modernizing?”

I can’t stand to see converted programs not gone through and given descriptive tag names.

I think those are the most least descriptive and lazy.

OEMs, I’m looking at you.

Rockwell was actually going to do this for us for a program in a modernization project. Went through explaining how the program would be converted and tested by their engineers and how great it would be.

Me: “Are you going to rename the tags to descriptive names?”

Rockwell: “No...”

Me: “So what service are you offering again? I thought we were modernizing?”

jgreenewv

Lifetime Supporting Member

What about buffering a float to 20 different F8_## tags in a converted 500 program?

I can’t stand to see converted programs not gone through and given descriptive tag names.

YES! Four years in and I'm still cleaning up converted programs left by my predecessor. I can't fathom why he didn't spend a little time creating proper tag names. Then again, his code on two identical machines was often completely different, so...

Similar Topics

I need help in trying to retreive the descriptive part of a ladder logic to help me troubleshoot the machine...somebody wrote it and I am having a...

- Replies

- 9

- Views

- 3,047

Hi, I'm having an issue in crimson 3.0 when I create a programme using a case statement referencing a fault word that each bit needs to change the...

- Replies

- 1

- Views

- 75

Has anyone ever seen where you have a tag reading from the plc in scada. In this instance it's just a PEC, I set it up on one scada terminal and...

- Replies

- 0

- Views

- 74

I want to set user security level based on the value of a tag in my PLC called "ActiveUser". That tag will contain the A-P code which we use for...

- Replies

- 6

- Views

- 199

My current situation is a follows:

I have two similar 1769 controllers with similar programs. Both have a UDT array that is being used to store...

- Replies

- 6

- Views

- 226