Hi, people!.

Need your wisdom for this doubt I'm having.

I need to program several water loops with a cooling system (0-100% glicol valve).

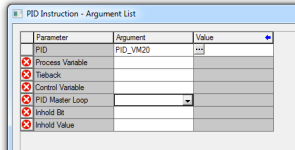

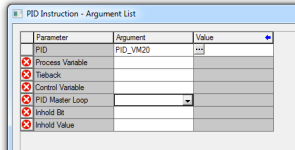

I've started taking a look at the PID function in RSLogix5000 (V31), but I've realized that this function only has "COntrol Variable" (for the valve control) and "Process Variable" (for the temperature measurement), but there is not a place where I can asign the SetPoint Variable:

Image1

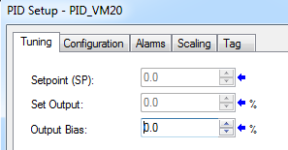

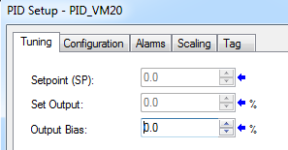

In the PID configuration, there is a SP FIeld but it seems is only gonna work in a manual mode.

Image2

So, I can't refer an HMI tag (i.e.) as a SP for this PID function?.

Thanks for your help.

Need your wisdom for this doubt I'm having.

I need to program several water loops with a cooling system (0-100% glicol valve).

I've started taking a look at the PID function in RSLogix5000 (V31), but I've realized that this function only has "COntrol Variable" (for the valve control) and "Process Variable" (for the temperature measurement), but there is not a place where I can asign the SetPoint Variable:

Image1

In the PID configuration, there is a SP FIeld but it seems is only gonna work in a manual mode.

Image2

So, I can't refer an HMI tag (i.e.) as a SP for this PID function?.

Thanks for your help.