You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Let’s practice brain!

- Thread starter Ukrainian

- Start date

93lt1

Member

rsdoran said:Ifn ya have a problem with this "test" just look up or think about using 3 & 4 way light switches. This would be a roll your own example.

Ron,

I want to see your solution...

Rube

Member

Maybe, Allen, maybe

Ah--but does the voltage drop across the lamp leave enough voltage to sound the buzzer?

Ah--but does the voltage drop across the lamp leave enough voltage to sound the buzzer?

Last edited:

mmw

Member

appears that the dastardly controllogix has corrupted Allen's thinking

93lt1

Member

Re: Maybe, Allen, maybe

Sure... It's a 240V circuit, 120V 100W light and 120V 100W buzzer.

Rube said:Ah--but does the voltage drop across the lamp leave enough voltage to sound the buzzer?

Sure... It's a 240V circuit, 120V 100W light and 120V 100W buzzer.

Last edited:

rsdoran

Lifetime Supporting Member

I am looking at doing it with a truth table because that would be my weak point.

I dont have anything to draw it with at this time but here is one solution in written form.

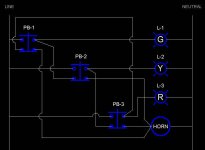

PB1 NO direct to L1 and thru PB2 NC to horn

PB2 NO direct to L2 and thru PB3 NC to horm

PB3 NO direct to L3 and thru PB1 NC to horn.

There is a problem with this if more than one button is pushed but the original question didnt mention more than one button being pushed.

Said it was a trick.

I dont have anything to draw it with at this time but here is one solution in written form.

PB1 NO direct to L1 and thru PB2 NC to horn

PB2 NO direct to L2 and thru PB3 NC to horm

PB3 NO direct to L3 and thru PB1 NC to horn.

There is a problem with this if more than one button is pushed but the original question didnt mention more than one button being pushed.

Said it was a trick.

Last edited:

Ken Moore

Lifetime Supporting Member

93lt1

Member

Mickey

Lifetime Supporting Member

deleted

Last edited:

rsdoran

Lifetime Supporting Member

that aint right...but thanks. I didnt explain correctly as usual.

I have it hand drawn but by the time I get it online someone will provide the answer...actually there is more than one answer.

I have it hand drawn but by the time I get it online someone will provide the answer...actually there is more than one answer.

Last edited:

93lt1

Member

rsdoran said:that aint right...but thanks.

Try explaining again...

bernie_carlton

Lifetime Supporting Member + Moderator

Here's another. It depends on BREAK BEFORE MAKE pushbuttons and only 1 pressed at a time

PB1

------] [-----+--------------------- Horn ---------------------

|

PB2 |

------] [-----+

|

PB3 | PB1 PB2 PB3

------] [-----+-----]\[-----+-----]\[-----+-----]\[-----+-------

| | | |

| LT1 | LT2 | LY3 |

+-----( )-----+-----( )-----+-----( )-----+

this is very similar to the proficiency exercise i give to newly-hired maintenance techs. i give them a momentary pushbutton, with both n.o. and n.c. contacts, a "cube-type" octal base timing relay, a pilot light, and an alarm buzzer.

the test consists of wirng the components so that 1.the light stays on all the time, 2.the buzzer comes on when the timer "times out", 3.the buzzer can be cancelled and the timer reset by pushing and releasing the pushbutton. then, 4.the timing cycle starts all over again.

when they are done, (or before they start, if they want), they are required to make a drawing of their project, freehand, with pin numbers, wire numbers, etc. with the idea that anyone could pick up that drawing and duplicate their circuit.

no time limit, (within reason). some guys, and gals can do it in about an hour, some took as long as 3 hours, but, as long as it worked and the drawing was accurate, the amount of time taken didn't matter.

btw, this was all 120 vac and i provide a short power cord with plug on one end so they can "smoke-test" their apparatus when they're done, (with the rest of us watching the power-up from the peanut gallery).

grouch

the test consists of wirng the components so that 1.the light stays on all the time, 2.the buzzer comes on when the timer "times out", 3.the buzzer can be cancelled and the timer reset by pushing and releasing the pushbutton. then, 4.the timing cycle starts all over again.

when they are done, (or before they start, if they want), they are required to make a drawing of their project, freehand, with pin numbers, wire numbers, etc. with the idea that anyone could pick up that drawing and duplicate their circuit.

no time limit, (within reason). some guys, and gals can do it in about an hour, some took as long as 3 hours, but, as long as it worked and the drawing was accurate, the amount of time taken didn't matter.

btw, this was all 120 vac and i provide a short power cord with plug on one end so they can "smoke-test" their apparatus when they're done, (with the rest of us watching the power-up from the peanut gallery).

grouch

You got it!

I don't think any other idea shall work from above.

Thanks to all of you.

I like your solution (but don't like your avatar).It is exactly what I've done. Is it your's, or someone else's solution?bernie_carlton said:Here's another. It depends on BREAK BEFORE MAKE pushbuttons and only 1 pressed at a time

I don't think any other idea shall work from above.

Thanks to all of you.

bernie_carlton

Lifetime Supporting Member + Moderator

My own solution. I have my method - when trying a set of assumptions doesn't work (contacts in series with thing controlled) back up and try other assumptions. In other words its the "When your head hurts from repeated running into a brick wall, step back and look for a door" method.

Similar Topics

Hello everyone!

So basically I have this PF 525 that no matter what I do won’t let me speed down. It always shows 66.66 Hz and the parameters to...

- Replies

- 11

- Views

- 1,181

35 years ago - 167 Souls were lost on Pipe Alpha (Oil Platform in the North Sea) all due to a failed management system See more information here...

- Replies

- 3

- Views

- 801

I have begun using 480VAC power supplies in my panels to keep heat from a transformer out of the panel. This works great if the panel is mounted...

- Replies

- 17

- Views

- 4,127

I am deciding on components for a bayed modular enclosure containing multiple VFDs (480V/350A/321Hp each) for a dynamometer. I am concerned given...

- Replies

- 7

- Views

- 1,700

Hi,

I am having trouble with the comms within FT view SE v11 (premanent license). I created an HMI program a while back which was working just...

- Replies

- 0

- Views

- 926