dayanyan

Member

Hello everyone! I'm very, VERY new to programming PLCs so I hope you bear my questions.

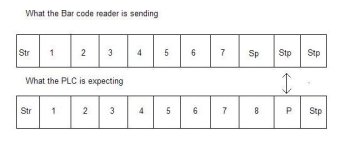

I'm using a NaiS FP2 PLC and Metrologic IS4225 bar code reader. I connected the two via RS232 and made a program (through FPWIN Pro) whose goal is to store information received by the bar code reader to a memory in the PLC. Simple enough, but I seem to be having trouble and I don't know whether or not it's because of my transmission settings or the program where it stores the information into the memory.

The bar code reader's transmission settings is as follows:

While the PLC has the following:

I configured the bar code reader to odd parity since the PLC's settings only has (odd, even, non and 0) parity. The rest, I followed the bar code reader's default settings. Did I understand this correctly? This is actually the first time I encountered a 'space' parity so I didn't know what to make of it.

As for the storing of information itself, my question is does the bar code reader automatically converts the information into ASCII format?

I'm sorry for the long post! Any reply would be greatly appreciated.

I'm using a NaiS FP2 PLC and Metrologic IS4225 bar code reader. I connected the two via RS232 and made a program (through FPWIN Pro) whose goal is to store information received by the bar code reader to a memory in the PLC. Simple enough, but I seem to be having trouble and I don't know whether or not it's because of my transmission settings or the program where it stores the information into the memory.

The bar code reader's transmission settings is as follows:

- space parity

- 9600 bps

- 7 data bits

- 2 stop data bits

While the PLC has the following:

- odd parity

- 9600 bps

- 8 data bits

- 1 stop data bits

I configured the bar code reader to odd parity since the PLC's settings only has (odd, even, non and 0) parity. The rest, I followed the bar code reader's default settings. Did I understand this correctly? This is actually the first time I encountered a 'space' parity so I didn't know what to make of it.

As for the storing of information itself, my question is does the bar code reader automatically converts the information into ASCII format?

I'm sorry for the long post! Any reply would be greatly appreciated.