Exercise #1 -- Filling the Batch Mixing Tank

Exercise #3 -- Continuous Operation

- From the Simulations Menu at the top of the screen, Select the Batch Mixing Simulation.

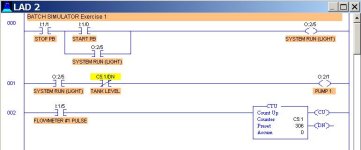

Using your knowledge of PLC counters, design a program to meet the following requirements:

- When the Start switch (I:1/0) is pressed, pump P1 will be energized and the tank will start to fill. The pulses generated by Flowmeter 1 should be used to increment a counter.

- When the count reaches a value where the tank is approximately 90% full, the pump is to be shut-off and and the control panels FULL light is to be energized.

- The filling operation is to halt immediately if the stop switch is pressed.

- While testing, utilize the "Reset Simulation" and the "Reset Timers and Counters" entries in the Simulations menu to re-start your program.

If correctly entered, the TOD (To BCD) instruction will take the integer value in the counters accumulator, convert it to Binary Coded Decimal, and then move (copy) this BCD value to the control panel LED display (O:4). The TOD instruction can be located in the Compute/Math group of instructions in the Edit Panel. Be sure to alter the Source entry to match the counter number you are using.

- Modify your program so that it meets the following additional requirements:

- The mixer will run for 8 seconds once the tank is full.

- When the mixing is complete, drain pump P3 is to be started and the tank is to be drained. Flowmeter 3 will be employed to decrement the existing counter, and draining will be allowed to continue till the counters accumulator reaches zero.

- Once the tank is empty again, pressing the Start switch will cause the sequence to repeat.

Exercise #3 -- Continuous Operation

- Modify your program so that the filling and emptying sequence will repeat continuously once it has been started by the initial pressing of the Start switch.

- Ensure that the RUN light is energized when the mixer or either pump is running.

- The STANDBY light should light and the process should halt when the Stop button is pressed.

- The process should restart where it left off if the the Start button is pressed following a Stop.