kekrahulik

Member

So what I don't see is a mechanical master - a roll that makes the web run at one speed. The closest thing that I see is if your winder is in speed control, it will set the web speed. However, without perfect knowledge of the winder diameter, the winder will not make the web run at constant speed.

So if you try to run your unwind diameter calculator, the calculation is flawed because you don't really know the web speed - only the web speed setpoint from fieldbus. That is not necessarily the web speed at every given moment.

So I think the winder needs speed control, but is there a diameter sensor there? Is there an intermediate roll that has an encoder for web speed feedback? Somehow the winder needs some feedback so it can half accurately run at web speed setpoint.

After that, I would suspect that the unwinds might be better off running in torque control with diameter sensors rather than diameter calc.

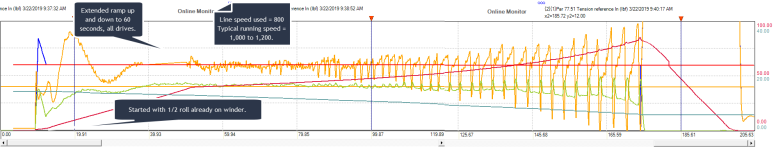

One thing to check during your next test. Can you track the actual webspeed at the winder to see how consistent it is.

At small diameters you will have your greatest challenge to control well - not surprising

So if you try to run your unwind diameter calculator, the calculation is flawed because you don't really know the web speed - only the web speed setpoint from fieldbus. That is not necessarily the web speed at every given moment.

So I think the winder needs speed control, but is there a diameter sensor there? Is there an intermediate roll that has an encoder for web speed feedback? Somehow the winder needs some feedback so it can half accurately run at web speed setpoint.

After that, I would suspect that the unwinds might be better off running in torque control with diameter sensors rather than diameter calc.

One thing to check during your next test. Can you track the actual webspeed at the winder to see how consistent it is.

At small diameters you will have your greatest challenge to control well - not surprising