RMA

Member

This is almost too embarrassing to ask, but I've been puzzling with this on and off for a couple of weeks now and I can't think of an elegant solution.

I've used the standard solution for monitoring the start up of motors (it also works for valves with only one feedback signal) often enough i.e.:

U #Motor

L #Response_Time

SE #Timer_Nr

UN # Motor

R #Timer_Nr

U #Timer_Nr

UN #Response

S # Fault

R #Motor

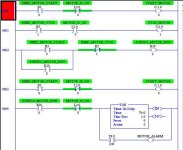

My problem is, how do I adapt this to motor driven switches where the PLC Output is a pulse to start the switch moving in one or the other direction, but there is no feedback signal from the switch motor to say that it's running. The same would apply to motor driven valves with two feedback signals.

The only thing I could come up with was handling the Open and Close commands separately and watching for the other command coming up in between and then also resetting the timer if the appropriate feedback signal came before the timer timed out. It works but does look messy.

This is an every day problem, somebody out there must have an elegant solution!

I've used the standard solution for monitoring the start up of motors (it also works for valves with only one feedback signal) often enough i.e.:

U #Motor

L #Response_Time

SE #Timer_Nr

UN # Motor

R #Timer_Nr

U #Timer_Nr

UN #Response

S # Fault

R #Motor

My problem is, how do I adapt this to motor driven switches where the PLC Output is a pulse to start the switch moving in one or the other direction, but there is no feedback signal from the switch motor to say that it's running. The same would apply to motor driven valves with two feedback signals.

The only thing I could come up with was handling the Open and Close commands separately and watching for the other command coming up in between and then also resetting the timer if the appropriate feedback signal came before the timer timed out. It works but does look messy.

This is an every day problem, somebody out there must have an elegant solution!