Showelljr

Member

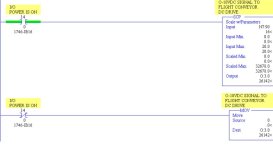

I have to take a slc 5/03 and use an analog out card ....number is 1746-n04v. To speed up or slow down a motor for a scrap belt. I know I can take the 160 analog follower model drive and set it up to receive 0 - 10vdc which is what the card will do. But the logic to get my PV900c so the operator can speed it up and down with the PV is kicking my tail. I tried to assign the buttons unsigned integar values but can't get it in my head right......I am great at troubleshooting and logic on the simple side but mov and copy and CPT instructions when you are passing them through a float file.....man I need some help......or at least some guidance.....

thanks

Steve

thanks

Steve