Hello,

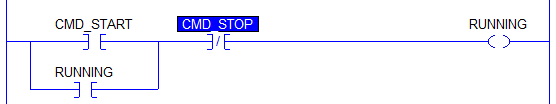

When it comes to process control (e.g starting/pausing/stopping a batch or sanitation function) with HMI pushbuttons, what is the standard or preferred or best types of buttons to use for START, STOP and PAUSE ? Should they be of type MOMENTARY OR MAINTAINED pushbuttons ?

Thanks

When it comes to process control (e.g starting/pausing/stopping a batch or sanitation function) with HMI pushbuttons, what is the standard or preferred or best types of buttons to use for START, STOP and PAUSE ? Should they be of type MOMENTARY OR MAINTAINED pushbuttons ?

Thanks