backendcode

Member

Hello Everyone,

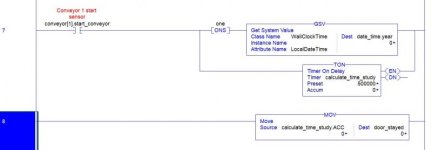

This might be a very stupid question but I need help to store the accumulator value before it resets.

So I am doing time study application and When part will come on the proximity sensor of my conveyor, it will store the date and time so I am using GSV instruction. at the same time, I also need to know how long part stayed there so I am using the timer and my accumulator value will give that time. So when I accumulator start increasing and I move that value to another tag(variable) DINT but when my time stops timing or condition become false before the timer, it resets the .acc value as well as the value of variable where I am moving my .acc value.

How Can I store the value to .acc everytime it increases!

I attached the pic and link of my code

https://ibb.co/kk6Kdk

Thanks

This might be a very stupid question but I need help to store the accumulator value before it resets.

So I am doing time study application and When part will come on the proximity sensor of my conveyor, it will store the date and time so I am using GSV instruction. at the same time, I also need to know how long part stayed there so I am using the timer and my accumulator value will give that time. So when I accumulator start increasing and I move that value to another tag(variable) DINT but when my time stops timing or condition become false before the timer, it resets the .acc value as well as the value of variable where I am moving my .acc value.

How Can I store the value to .acc everytime it increases!

I attached the pic and link of my code

https://ibb.co/kk6Kdk

Thanks