Part 3 – Coping with Large Demands for Compressed Air

Your current program should be suitable for maintaining the desired pressure range as long as

the plant air consumption remains relatively modest. As the plant air consumption approaches

100% capacity however, it becomes obvious that we will need to have both compressors running

in order to satisfy this increased loading.the plant air consumption remains relatively modest. As the plant air consumption approaches

100% capacity however, it becomes obvious that we will need to have both compressors running

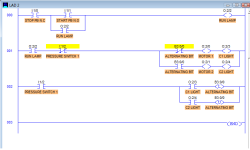

Modify your program so that the second pressure switch PE2 will detect when the storage tank

pressure drops below our current minimum setting of 110PSI. This situation will occur if a single

compressor is unable to keep up to the load and the tank pressure continues to drop. If and when

the pressure drops to 109PSI, the idle compressor should be started, and both compressors will

then continue to run until the tank is up to full pressure.pressure drops below our current minimum setting of 110PSI. This situation will occur if a single

compressor is unable to keep up to the load and the tank pressure continues to drop. If and when

the pressure drops to 109PSI, the idle compressor should be started, and both compressors will

It is likely that your modifications will also result in both compressors being run when the system

is first started and the tank pressure is initially being brought to within range of the pressure

switches. This action will reduce the time it takes to bring the plant air system up to pressure, and

is therefore considered desirable. Please ensure that your system does actually operate in this

fashion.

Once you have created your program, download it to the PLC and thoroughly test out its

operation at both 50% and 100% rates of flow. When at 50% loading, the compressors should

alternate with each taking a turn. At 100% loading, both compressors should engage once it is

detected that the pressure is continuing to drop.

Your program should now be able to handle both light and heavy demands for air quite

effectively. While this current solution likely performs as well as most systems employing relay

logic, with just a bit more effort you should still be able to even improve upon this. Before

continuing to the next part, run your system with the flow rate adjusted to 78%, 80%, and then

82%, and carefully note the result. You should now have a good idea of where improvements

please help me out i got this so far i can get the two dual compressors to alternate but i cant get the one dual compressor to go full then drain then both start up...