PLCS does not have much information on ROC FST programming, as it is an RTU for the Oil and Gas sector, Now that I have taught myself a bunch, I thought I'd start a thread to help others.

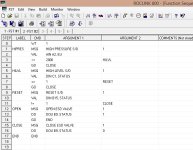

This is for the ROC300, ROC800, FB407, FB408, FB503, FB504, FB103, FB104, FB107 and is for FST Programming and general Configurations in Rocklink800. FST stands for Function Sequence Table. It is kind of similar to Basic programming but in a spreadsheet kind of layout.

A couple common practices are as follows:

1. Always start each FST with a WT (wait) command and ARG1 of generally 1. This is common practice, i am assuming it is to make sure the FST executes properly each scan.

2. Comments are not loaded into the ROC, and although you can have an offline version, it is more common practice (when you are not limited by the lines of code, for example a FB503 only allowed 2 FST's 300lines each) to use LBL's that describe each step as well as MSG Commands to tell you what is happening at each point as both are loaded into the ROC.

3. Make sure after writing the new code, to goto system>Flags in roclink800 and click save configuration, so that it doesnt lose your changes.

4. Typically FST1 is the shutdown logic, and the rest are for other functions, math and such, but it does not matter which is where as long as you have the FST's enabled to scan. to doublecheck that, in roclink800 goto Control>FST registers and check that they are enabled.

I Will Post some example logic to pick apart as this will be an evolving thread, but also if anyone needs help, they can comment on here and we can solve the issues together.

This is for the ROC300, ROC800, FB407, FB408, FB503, FB504, FB103, FB104, FB107 and is for FST Programming and general Configurations in Rocklink800. FST stands for Function Sequence Table. It is kind of similar to Basic programming but in a spreadsheet kind of layout.

A couple common practices are as follows:

1. Always start each FST with a WT (wait) command and ARG1 of generally 1. This is common practice, i am assuming it is to make sure the FST executes properly each scan.

2. Comments are not loaded into the ROC, and although you can have an offline version, it is more common practice (when you are not limited by the lines of code, for example a FB503 only allowed 2 FST's 300lines each) to use LBL's that describe each step as well as MSG Commands to tell you what is happening at each point as both are loaded into the ROC.

3. Make sure after writing the new code, to goto system>Flags in roclink800 and click save configuration, so that it doesnt lose your changes.

4. Typically FST1 is the shutdown logic, and the rest are for other functions, math and such, but it does not matter which is where as long as you have the FST's enabled to scan. to doublecheck that, in roclink800 goto Control>FST registers and check that they are enabled.

I Will Post some example logic to pick apart as this will be an evolving thread, but also if anyone needs help, they can comment on here and we can solve the issues together.