From a previous thread someone suggested I use a Micrologix 1500 LRP for recipe control as this has 48K bytes. I am giving this method a little more thought here.

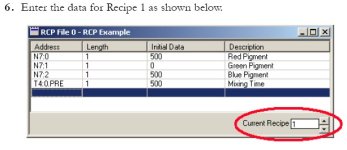

This is the situation; using a barcode scanner to scan a barcode that will automatically send values to an HMI to reduce setup times. The way I want the program to be set up is once the barcode scanner has scanned a barcode, search through 200 part numbers (use indexed addressing here) and if that part# is there, move the value from where the indexed address found the same part# to a different address (let's just say N7:0). From here, I would also turn on a bit which would activate the recipe command which would have N7:0 as the recipe number as it's address.

If this is a bad way to set this up then let me know, the reason I have it this way is because we will have new part's coming in so we would like for the operator (accompanied by a supervisor who will have a password to go to a specific screen) to be able to create a recipe right on the HMI. I realize that this can be bad but that is why the password would be there.

Here finally comes the question, based on if the answer is yes will prompt even more questions. I am reading that the MicroLogix 1500 LRP has 10K memory for the user program and 4K memory for user data. Can I use the 10K memory if I go over the limit of 4K memory data? I believe you can but I might have that backwards. The reason I know I will go over this limit is because I need to search through approx 200 part#'s, so at 200 strings at 82 characters plus the integer for the field length, is well over that limit. Which leads to a follow up question if I can use th 10K data for also user data, I know for a fact that the part#'s will be only like 20 characters long so I could use in theory 11(11 due to field length) 16 bit integers and then just move those to a string. A problem I can see with this is I will need more than one data type of integers to do this (eg N9,N10...),so that could be a problem to. If there was a way to compare the part# to a string in the recipe file would be great as well, just not sure that is possible.

Please post your comments/suggestions on this one!

This is the situation; using a barcode scanner to scan a barcode that will automatically send values to an HMI to reduce setup times. The way I want the program to be set up is once the barcode scanner has scanned a barcode, search through 200 part numbers (use indexed addressing here) and if that part# is there, move the value from where the indexed address found the same part# to a different address (let's just say N7:0). From here, I would also turn on a bit which would activate the recipe command which would have N7:0 as the recipe number as it's address.

If this is a bad way to set this up then let me know, the reason I have it this way is because we will have new part's coming in so we would like for the operator (accompanied by a supervisor who will have a password to go to a specific screen) to be able to create a recipe right on the HMI. I realize that this can be bad but that is why the password would be there.

Here finally comes the question, based on if the answer is yes will prompt even more questions. I am reading that the MicroLogix 1500 LRP has 10K memory for the user program and 4K memory for user data. Can I use the 10K memory if I go over the limit of 4K memory data? I believe you can but I might have that backwards. The reason I know I will go over this limit is because I need to search through approx 200 part#'s, so at 200 strings at 82 characters plus the integer for the field length, is well over that limit. Which leads to a follow up question if I can use th 10K data for also user data, I know for a fact that the part#'s will be only like 20 characters long so I could use in theory 11(11 due to field length) 16 bit integers and then just move those to a string. A problem I can see with this is I will need more than one data type of integers to do this (eg N9,N10...),so that could be a problem to. If there was a way to compare the part# to a string in the recipe file would be great as well, just not sure that is possible.

Please post your comments/suggestions on this one!