drbitboy

Lifetime Supporting Member

@GrizzlyC, I am curious: how much noise in the temperature measurement e.g. how much in the raw signal, how much in the 10s-filtered signal?

@GrizzlyC, I am curious: how much noise in the temperature measurement e.g. how much in the raw signal, how much in the 10s-filtered signal?

Also, what is the target control range? +/- 0.05? +/-0.01?

...

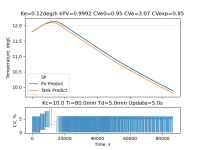

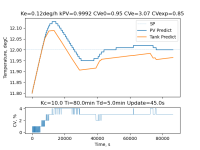

Initial results are showing the valve is winding down before the PV crosses the SP. ...

Ive got a new tank with the following parameters in it

p = 10

i = 80

d = 5

Execution time = 5sec

not that my model is Truth, but it predicts the following result...

Summary

Get rid of that Td!

Maybe he has DSmoothing := TRUE?

From memory this adds a filter of 1/10th your derivative time constant to your derivative term, but I couldn't find the reference to this calculation.

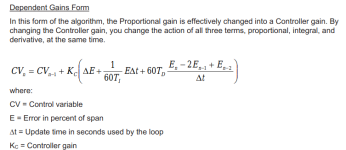

Wow, that is an interesting idea. So if a derivative term is calculated as 10% CV movement at an update, DSSmoothing only adds 1/10th of that, i.e. 1% CV, on that update, and then accumulates 9% for the next update, where it will cause 0.9% CV on the next update, leaving 8.1% in the accumulator, etc., along with accumulating any other D-driven CV changes on each scan?

Why does the CV change in 1% steps in post #98?

...

I can see the control output changing in steps if the feedback resolution is poor.

Maybe he has DSmoothing := TRUE?

From memory this adds a filter of 1/10th your derivative time constant to your derivative term, but I couldn't find the reference to this calculation.

That use to be a problem with hydraulic valves. The answer was to super impose dither signal. This could be as much as adding or subtracting 20% of the full range of the control signal on top of the actual signal. The dither kept the valve from every really stopping so valve didn't suffer from the stick slip or Stribeck friction.They also offset the CV at 0% to be around 7ma output to the valve positioner (just under 20%), which is just before the valve actually opens, as determined by bench testing.