drbitboy

Lifetime Supporting Member

@GrizzlyC: did the PIDE ever settle down? If yes, what were the final values of CV it was bouncing between?

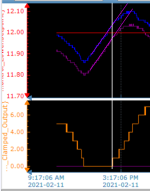

@drbitboy, I think you mean ~7% PID output, not 7mAIs anyone else curious about, or baffled by its character? I am referring specifically the sharp "V" reversals at the minima.

I'm sure it can be modeled mathematically, but I have been trying, without success, to come up with a physical model to explain this behavior.

Is it possible that the glycol coolant valve sticks at its maximum open value until it is is commanded to fully close (at ~7ma)?

IF AnalogOut_mA > (ActualValvePosition_mA + 1.5mA) THEN

ActualValvePosition_mA := AnalogOut_mA - 1.5mA;

ELSIF AnalogOut_mA < (ActualValvePosition_mA - 1.5mA) THEN

ActualValvePosition_mA := AnalogOut_mA + 1.5mA;

END_IF

ActualValvePosition_mA | % FLOW

5.5mA | 0%

18.5mA | 100% FlowOh I apologise. I interpreted your sentence as "gets stuck at 7% when the valve is commanded to close." Instead of what you actually wrote.

When the PID output goes from 1% to 0%, the mA is set to 4mA, and that explains the sharp V.

#14

I think my confusion came because the valve is not commanded to fully close at 7mA.

I have the valve go to complete closed position 4ma when at 0%CV to ensure the valve is closed and move it to 7ma at 1%CV

@drbitboy, in post 14, Grizzly says 0% is 4 mA, 1% is 7mA.

But it still does not explain the character of the dynamics.

When I look at the trend and see the PV change direction shortly after the CV reaches zero, my inclination is to think that there might not be too much pure deadtime. If true, and the CV has room to work, it could very well be possible to significantly reduce or eliminate the amplitude of oscillation.

From the plots above I see the orange output start to increase before 3:17PM There are 6 hours between the vertical markers so the control output must start increasing before 3PM.