Hi,

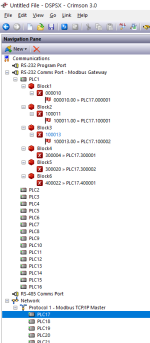

I have a situation at my plant, where I need to interface my existing PLC with some field devices Via Modbus Interface. I can not change the program of existing PLC, but I have Modbus slave addresses and register details that are required to communicate with field devices. I want to connect PLC with a gateway that can read the Modbus requests from PLC for each slave (via a single Modbus RTU Communication Port) and poll it intelligently to new addresses via ethernet interface. Attached is a snapshot. Can someone refer how can I achieve this gateway functionality?

I have a situation at my plant, where I need to interface my existing PLC with some field devices Via Modbus Interface. I can not change the program of existing PLC, but I have Modbus slave addresses and register details that are required to communicate with field devices. I want to connect PLC with a gateway that can read the Modbus requests from PLC for each slave (via a single Modbus RTU Communication Port) and poll it intelligently to new addresses via ethernet interface. Attached is a snapshot. Can someone refer how can I achieve this gateway functionality?