Just found out that the HMI you have will not diplay or input float numbers only integers, you cannot use integer DS type registers on the analogs, I have been looking at the HMI software numeric input & display & I certainly cannot find any way of changing it, still you get what you pay for

The only way would be to multiply the float by 10 (1 decimal place) then convert it to an integer. or if you do not need decimal places then just convert from float to integer.

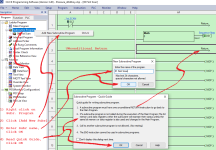

Just looked it appears there is no instruction but it does seem you can use the copy function to copy a float to integer.

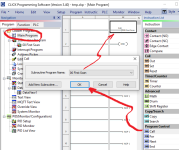

EDIT: Just closed it down & opened it up again & it now allows me to add a float, it's definitely buggy

The only way would be to multiply the float by 10 (1 decimal place) then convert it to an integer. or if you do not need decimal places then just convert from float to integer.

Just looked it appears there is no instruction but it does seem you can use the copy function to copy a float to integer.

EDIT: Just closed it down & opened it up again & it now allows me to add a float, it's definitely buggy

Last edited: