Kevin1793

Member

Hi everyone!

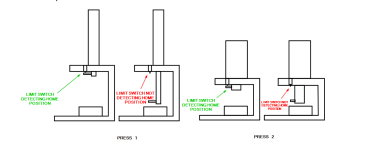

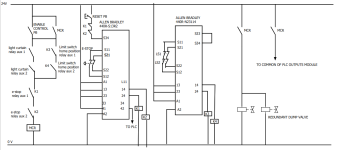

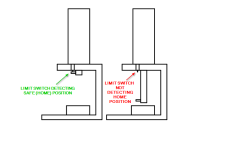

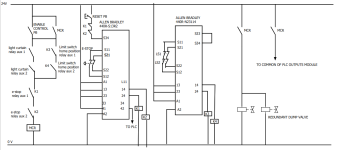

I'm working on the controls design of a semi-automatic pneumatic vertical press. The machine will consist of two double-acting cylinders with 5/3 closed center valves and pilot-operated check valves on cylinders ports to keep them in position when no power is applied to the solenoids. Everything controlled by a non-safety PLC to automate the operation. An e-stop, light curtains and a dual dump valve hard-wired to safety relays (all dual channel) with auxiliary force-guided relays will be the safety devices. If the e-stop is pressed or light curtains are blocked, the dump valve will exhaust the air and cut the power of the plc outputs off. However, I don't want this to happen every time curtains are blocked since interrupting them a couple of times to load parts during machine cycle will be part of the process. I only want this behavior if the cylinders are retracted (home position) and (maybe) during upstroke. Blocking curtains during downstroke will definitely stop all motion and cut all power.

Is this logic allowed? If so, how can I do it? I’ve seen many presses working this way, but I’m a bit confused how to do it in a safe way.

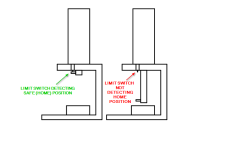

I know the muting modules but is there any other way? How about to place a safety limit switch to detect when cylinder is retracted so that if the curtains are blocked and the cylinder is in other position than home the power and air will be cut off. Is this approach safe?

I’ve attached some diagrams illustrating my idea and the safety circuit i got so far. Any help will be appreciated.

I'm working on the controls design of a semi-automatic pneumatic vertical press. The machine will consist of two double-acting cylinders with 5/3 closed center valves and pilot-operated check valves on cylinders ports to keep them in position when no power is applied to the solenoids. Everything controlled by a non-safety PLC to automate the operation. An e-stop, light curtains and a dual dump valve hard-wired to safety relays (all dual channel) with auxiliary force-guided relays will be the safety devices. If the e-stop is pressed or light curtains are blocked, the dump valve will exhaust the air and cut the power of the plc outputs off. However, I don't want this to happen every time curtains are blocked since interrupting them a couple of times to load parts during machine cycle will be part of the process. I only want this behavior if the cylinders are retracted (home position) and (maybe) during upstroke. Blocking curtains during downstroke will definitely stop all motion and cut all power.

Is this logic allowed? If so, how can I do it? I’ve seen many presses working this way, but I’m a bit confused how to do it in a safe way.

I know the muting modules but is there any other way? How about to place a safety limit switch to detect when cylinder is retracted so that if the curtains are blocked and the cylinder is in other position than home the power and air will be cut off. Is this approach safe?

I’ve attached some diagrams illustrating my idea and the safety circuit i got so far. Any help will be appreciated.

Last edited: