Dear,

Pipe size is 1200mm and I need to install sensor for measuring flow, I check krohne and Toshiba for electromagnetic flowmeter for partial filled pipes, maximum pipe size is 1000mm for krohne and maximum pipe size for Toshiba is 600mm, so it is not possible to use electromagnetic flowmeter for either Krohne or Toshiba.

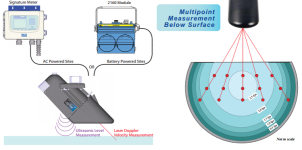

one of the solution that can be used is from the below

https://vimeo.com/69531544

where it uses top and side sensors (ultrasonic for top and velocity for side) however, looking at the flow sensor chamber, the velocity sensor on the side seems it doesn't fit.

attached are the flow sensor chamber, appreciate any feedback on this issue.

thank you!

Charbel

Pipe size is 1200mm and I need to install sensor for measuring flow, I check krohne and Toshiba for electromagnetic flowmeter for partial filled pipes, maximum pipe size is 1000mm for krohne and maximum pipe size for Toshiba is 600mm, so it is not possible to use electromagnetic flowmeter for either Krohne or Toshiba.

one of the solution that can be used is from the below

https://vimeo.com/69531544

where it uses top and side sensors (ultrasonic for top and velocity for side) however, looking at the flow sensor chamber, the velocity sensor on the side seems it doesn't fit.

attached are the flow sensor chamber, appreciate any feedback on this issue.

thank you!

Charbel