MorphuisOGrady

Member

Hi All,

Has anyone any experience in controlling a non linear valve with a PID?

Traditionally this valve is controlled on flow but would like to experiment with pressure and omit the flowmeter eventually.

What I am trying to achieve is a stable pressure differential across the valve so will install 2 pressure transmitters.

As the ball valve to be controlled is nonlinear I was hoping for some ideas on how to achieve this. I am using an AB Compactlogix with the PIDE instruction contained in a PlantPAx wrapper AOI.

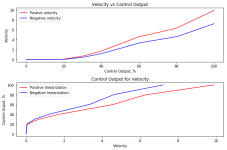

I have a valve open position v flow model from the valve manufacturer and can see clearly it's nonlinear.

Secondly if I can achieve this form of control I would like to calculate the flow. From a test from valve supplier I can see the flow vs valve stroke position in steps of 5%.

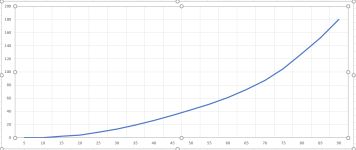

Is anyone aware of a calculation to get flow for this so I can break it down over 100 points instead (1 % steps) instead of 20 points (5% steps).

Has anyone any experience in controlling a non linear valve with a PID?

Traditionally this valve is controlled on flow but would like to experiment with pressure and omit the flowmeter eventually.

What I am trying to achieve is a stable pressure differential across the valve so will install 2 pressure transmitters.

As the ball valve to be controlled is nonlinear I was hoping for some ideas on how to achieve this. I am using an AB Compactlogix with the PIDE instruction contained in a PlantPAx wrapper AOI.

I have a valve open position v flow model from the valve manufacturer and can see clearly it's nonlinear.

Secondly if I can achieve this form of control I would like to calculate the flow. From a test from valve supplier I can see the flow vs valve stroke position in steps of 5%.

Is anyone aware of a calculation to get flow for this so I can break it down over 100 points instead (1 % steps) instead of 20 points (5% steps).