In Allen-Bradley world (Controllogix Rev 30 controller) is PID scaling ALWAYS set to match the input card / sensor scaling?

I am simulating a process in a test lab, where I attempt to maintain a steady pressure reading using a PID while introducing changes to the system.

My Transducer is 4 to 20 mA = -10.0 psi to 450psi.

My logic is in kPa(because the system we are simulating is programmed this way). So my sensor range is ~-69 to 3103 kPa

The process I am simulating has a min pressure of 0 kpa and a max pressure of 80 kPa. So, you can see that I am only using a tiny portion of the sensor's range.

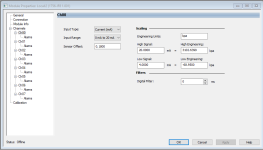

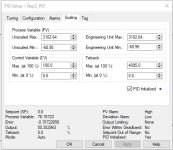

When I set my PID Scale tab to match the sensor scaling (unscaled and engineering min/max), I have to use huge P gains to get the process under control. Huge being P gain of 175 or so. It seems to control it fine when I do this, but I'm not accustomed to seeing values this high.

I make the PID scale max and min something more realistic to the process. Say min 0 and max 310 kPa (I did this because it was 10% of sensor range and easy math) my gains come down into the real world. But it is my understanding that this is incorrect.

So, are large gain numbers just a part of having a sensor with a kPa range that large, or should I adjust my scale to bring them down, or do I have something else going on?

Thanks for your time!

I am simulating a process in a test lab, where I attempt to maintain a steady pressure reading using a PID while introducing changes to the system.

My Transducer is 4 to 20 mA = -10.0 psi to 450psi.

My logic is in kPa(because the system we are simulating is programmed this way). So my sensor range is ~-69 to 3103 kPa

The process I am simulating has a min pressure of 0 kpa and a max pressure of 80 kPa. So, you can see that I am only using a tiny portion of the sensor's range.

When I set my PID Scale tab to match the sensor scaling (unscaled and engineering min/max), I have to use huge P gains to get the process under control. Huge being P gain of 175 or so. It seems to control it fine when I do this, but I'm not accustomed to seeing values this high.

I make the PID scale max and min something more realistic to the process. Say min 0 and max 310 kPa (I did this because it was 10% of sensor range and easy math) my gains come down into the real world. But it is my understanding that this is incorrect.

So, are large gain numbers just a part of having a sensor with a kPa range that large, or should I adjust my scale to bring them down, or do I have something else going on?

Thanks for your time!