AutomationTechBrian

Lifetime Supporting Member

I'm troubleshooting a customer's machine, and I've been racking my brain trying to figure out an answer to a question of where a value is being written to a tag.

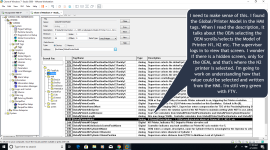

The customer's machine has an "N2" printer hooked up to this box making machine. They powered up the machine the other morning and the HMI no longer displayed the N2 printer (with all of it's set-up parameters). It displayed an N1 printer. They don't have an N1 printer. The customer has the RSLogix 5000 file, as well as the Panelview 700 file. I downloaded and installed version 17.01 on an XP virtual machine, and loaded the Panelview Plus 700 file (version 7) on my FactoryView Studio ME, version 9, to re-load the programs and then troubleshoot the issues.

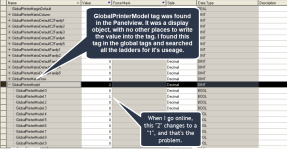

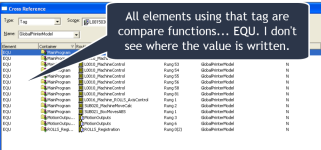

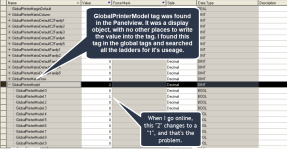

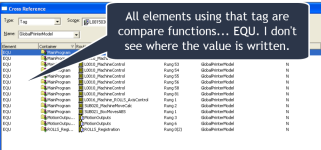

The N2 printer did not show up. So, I found the screen with the object that displays the printer name and looked at the tag-name. Then I looked in the PLC program and found the tag and checked where it was used in the program. In all the cross-reference locations, the function was EQU... where the value of the DINT was compared. I could not find anywhere where the value was written.... just compared.

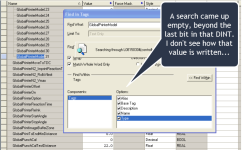

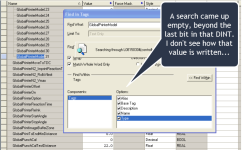

So, I figured it must be coming from the HMI. So I checked the tag browser in the HMI and the only location that tag was being used was for the display object that I was referencing. I just can't figure it out and I need some more experienced eyes to look.

I'm a independent tech... so I need to know a little about a lot of legacy equipment... from Siemens to Automation Direct. I'm not able to focus on one software package long enough to really build expertise. The RSLogix 5000 is fairly new to me. I had it in school, about 10 years ago, but just got to purchase my own copy about a month ago. I have a couple of customers who have SLC's, so I've spent much more time in Logix 500. I figure the answer is simple... but I just can't figure out where to look.

Attached are some great pics to get things started. I won't go back on-site until I have something figured out. It's an 90 min. drive, and I've got good coffee here at home.

Any thoughts?

The customer's machine has an "N2" printer hooked up to this box making machine. They powered up the machine the other morning and the HMI no longer displayed the N2 printer (with all of it's set-up parameters). It displayed an N1 printer. They don't have an N1 printer. The customer has the RSLogix 5000 file, as well as the Panelview 700 file. I downloaded and installed version 17.01 on an XP virtual machine, and loaded the Panelview Plus 700 file (version 7) on my FactoryView Studio ME, version 9, to re-load the programs and then troubleshoot the issues.

The N2 printer did not show up. So, I found the screen with the object that displays the printer name and looked at the tag-name. Then I looked in the PLC program and found the tag and checked where it was used in the program. In all the cross-reference locations, the function was EQU... where the value of the DINT was compared. I could not find anywhere where the value was written.... just compared.

So, I figured it must be coming from the HMI. So I checked the tag browser in the HMI and the only location that tag was being used was for the display object that I was referencing. I just can't figure it out and I need some more experienced eyes to look.

I'm a independent tech... so I need to know a little about a lot of legacy equipment... from Siemens to Automation Direct. I'm not able to focus on one software package long enough to really build expertise. The RSLogix 5000 is fairly new to me. I had it in school, about 10 years ago, but just got to purchase my own copy about a month ago. I have a couple of customers who have SLC's, so I've spent much more time in Logix 500. I figure the answer is simple... but I just can't figure out where to look.

Attached are some great pics to get things started. I won't go back on-site until I have something figured out. It's an 90 min. drive, and I've got good coffee here at home.

Any thoughts?