OkiePC

Lifetime Supporting Member

This not going to be as easy as I had thought. I have found about 1 in 10 customers in the water industry with any existing wiring diagrams or documented programs. I am going to be spending a lot of hours in "tug test" mode following wires all over the place. . . which is hard to do from 120 miles away. It is not like my other jobs where I could walk back and forth between my work place and my machinery when I ran into missing info. I have been chuggin' along pretty quick with the A/B systems I have encountered, but today....

I am lost in DirectSOFT land, and starting to get a little frustrated. I am trying to get around in a DL06 project using DirectSoft 6. I have uploaded and saved two programs from a customer site. Of course there is no documentation, no electrical diagrams, no nothing.

So, I need to figure out everything from nothing which has been easy for me with Allen Bradey PLCs, but I am having a hard time with DirectSoft.

I did find Bernie Carlton's web page on the subject and found it quite useful in general.

Questions remaining:

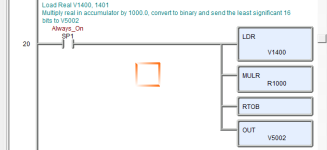

1) How do I track down the I/O data points (including an add on analog module) in the PLC memory/data tables? I understand that the discrete points are X and Y, but what about analog add on cards?

2)Where is a list of "special registers" that I can refer to for e DL06? Apparently there are a lot of SP contacts that mean something, but what?

3) PID. I am pretty sure there is a PID block in at least one of these projects, but how do I see it, and can I see it when offline?

4)Data tables. I have found the data view windows, but do I have to fill in the blanks? Is there some easier way to set up my work space so I can quickly jump between a data point in an instruction to a window with a cross reference? Can I see the values stored in those locations when offline?

Thanks for any advice.

Paul

I am lost in DirectSOFT land, and starting to get a little frustrated. I am trying to get around in a DL06 project using DirectSoft 6. I have uploaded and saved two programs from a customer site. Of course there is no documentation, no electrical diagrams, no nothing.

So, I need to figure out everything from nothing which has been easy for me with Allen Bradey PLCs, but I am having a hard time with DirectSoft.

I did find Bernie Carlton's web page on the subject and found it quite useful in general.

Questions remaining:

1) How do I track down the I/O data points (including an add on analog module) in the PLC memory/data tables? I understand that the discrete points are X and Y, but what about analog add on cards?

2)Where is a list of "special registers" that I can refer to for e DL06? Apparently there are a lot of SP contacts that mean something, but what?

3) PID. I am pretty sure there is a PID block in at least one of these projects, but how do I see it, and can I see it when offline?

4)Data tables. I have found the data view windows, but do I have to fill in the blanks? Is there some easier way to set up my work space so I can quickly jump between a data point in an instruction to a window with a cross reference? Can I see the values stored in those locations when offline?

Thanks for any advice.

Paul

Last edited: