karlek

Member

There are cable tools for exactly this purpose.

But I just use a sharp knife and my surgeon-like senses.

Can you provide some link or name of the tool, please?

There are cable tools for exactly this purpose.

But I just use a sharp knife and my surgeon-like senses.

Check this video tutorial:

https://youtu.be/EY32tfxohQ4

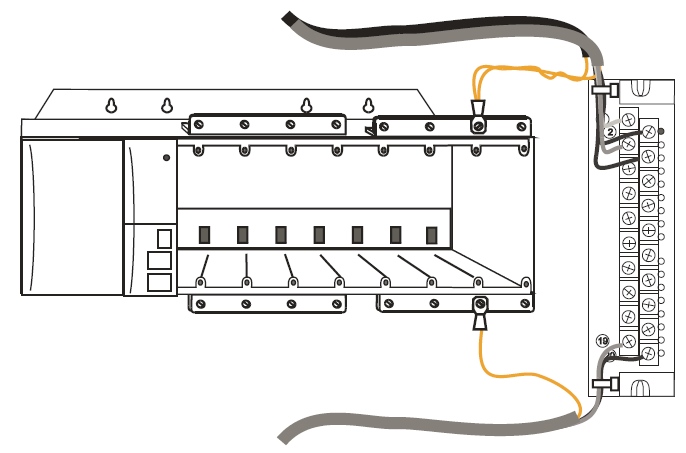

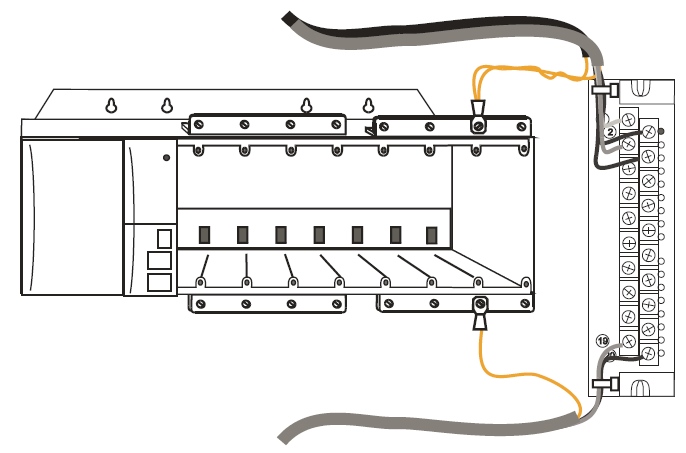

shield grounds on the rack right at the I/O modules on one PAC I work on:

Search for "cable dismantling tool".

These tools are mainly for stripping the end of cables. To take out a section in the middle, you have to make 2 circular cuts, and then a slit from one circular cut to the other.

DO and DON'T,

so going along with my shielding question i have run into a problem and hope some of the people more experienced then I in this thread will chime in. i will try and keep it to the point.

4-20ma signal from a linear transducer. solid signal when idle, once a VFD turns on in the machine the signal is still steady, just inaccurate. the transducer measures distance traveled of an object and while that object is moving if you watch the PLC its about 2 inches off from real world. by that i mean when i let off the HMI button and the object stops traveling, the number on the screen that was just say 52 is now 54, and if im shooting to stop at 50 with a window of + or - an inch in the PLC code, you can see the issue. i do not own an oscilloscope.

the transducer has a 4 wire shielded cable run to it, only 3 wires are utilized, 24vdc +, 4-20ma output signal, ground. the three wires go to a junction box on the machine and are all landed on pass through terminal blocks. inside the cabinet the the ground and the shield are landed on a pass through terminal block right near the analog input card, the other side of the terminal block goes directly to the grounding lug within the cabinet. The transducer is mounted on a solid piece of metal within the machine, BUT between the transducer body and the metal there is a piece of plastic because it was thought by someone else that it would "help with the noise". The bolts used to mount said transducer to the metal plate are also plastic.

where should i start to attempt to solve my issue? i believe my first order of business should be to get rid of that plastic thats in there because from what i can read, at least from a different manufacturer, the transducer body itself should be grounded. any and all advice welcome.