alexbeatle

Member

Hello all,

This is an indirect PLC question.

When detecting distance to the wheels (laid flat, rims up), ultrasonic sometimes gives erroneous readings. I'm suspecting this is due to the uneven surface of the rims, but then ultrasonics have wide area scanning due to their sound cone, don't they?

Any suggestion is appreciated.

Using this sensor:

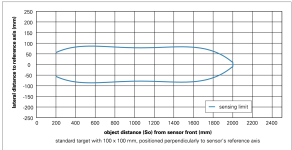

Ultrasonic UMT 30-3400-A-IUD-L5

https://www.sensopart.com/en/products/ultrasonic-sensors/ultrasonic-sensors/umt-30-3400-a-iud-l5.html

This is an indirect PLC question.

When detecting distance to the wheels (laid flat, rims up), ultrasonic sometimes gives erroneous readings. I'm suspecting this is due to the uneven surface of the rims, but then ultrasonics have wide area scanning due to their sound cone, don't they?

Any suggestion is appreciated.

Using this sensor:

Ultrasonic UMT 30-3400-A-IUD-L5

https://www.sensopart.com/en/products/ultrasonic-sensors/ultrasonic-sensors/umt-30-3400-a-iud-l5.html