jimpad

Member

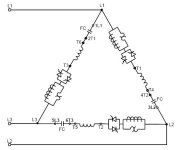

I've been asked to install the main motor wye-delta starter in my plc control panel for a machine. I've seen this setup many times where the starter and controls are in the same panel although I've never done the design on the starter only the plc and logic. previously I've seen Nema size 5 and 6 starters installed. Now, I have to supply the starter.

1. How do I choose between IEC, NEMA? (Does this question even make sense?)

2. Does anyone know where I can find all the components already installed on a backplane for mounting in my panel? So far I've only been able to find the complete starter and enclosure at AllenBradley but that doesn't leave room for the plc and auxilliaries.

3. If I have to build it up myself, does anyone know of a cookbook approach where the basic steps are identified?

Thanks,

Jim

1. How do I choose between IEC, NEMA? (Does this question even make sense?)

2. Does anyone know where I can find all the components already installed on a backplane for mounting in my panel? So far I've only been able to find the complete starter and enclosure at AllenBradley but that doesn't leave room for the plc and auxilliaries.

3. If I have to build it up myself, does anyone know of a cookbook approach where the basic steps are identified?

Thanks,

Jim