TheDude_Abides

Member

OP

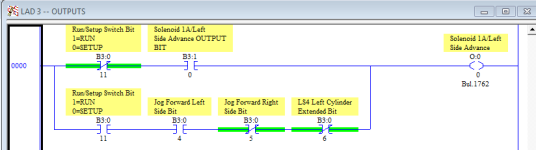

I am fairly new to programming so this will be something to build on. I am familiar with intergers and what they do but Ive mostly just been programming ladder logic. From a quick good search it does seem to make navigating easier but there seems to be a learning curve.