Dan_S

Member

I'm having an scaling issue using an F0-04THM module card with a Directsoft D0-05DR PLC. My issue is this; the temp data in the PLC has one implied decimal point. A normal numeric indicator can accommodate this, but the line trend graph in the C-More EA9 cannot. My two indicators show the temps, and they are accurate and within .3° from each other at ambient, and respond properly when hit with a heat gun. The graph data, however, is off by a factor of ten, so it's displaying 740° at ambient.

How can I use the logic provided by the F0-04THM and divide that by 10 without affecting the output I have at V2000? I would like to see the numeric display match the chart values, and I don't care to divide every cell in a huge data log by 10 to get to the correct value.

Also, I am using channels 1 and 4, and have the +/- of 2 and 3 jumpered, as well as all the commons.

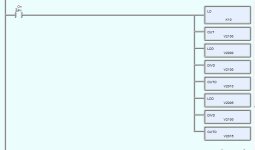

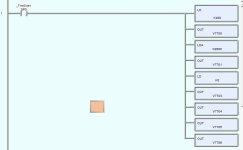

I attached what AD gives as the logic for reading the temp card.

"It's surety I crave, and have none."

Thanks for any assistance.

How can I use the logic provided by the F0-04THM and divide that by 10 without affecting the output I have at V2000? I would like to see the numeric display match the chart values, and I don't care to divide every cell in a huge data log by 10 to get to the correct value.

Also, I am using channels 1 and 4, and have the +/- of 2 and 3 jumpered, as well as all the commons.

I attached what AD gives as the logic for reading the temp card.

"It's surety I crave, and have none."

Thanks for any assistance.