I've read that the correct data frame/standard for Modbus over RTU is 8 data bits and 1 stop bit with even parity. Is that correct?

There is no 'correct' data frame for Modbus RTU other than a requirement for 8 data bits. The correct setting is to have both ends have identical serial settings.

The Modbus specification that says RTU is 8 data bits (Modbus ASCII is 7 bit) and specifies that No parity uses two stop bits, whereas even or odd parity use one stop bit. That flies in the face of conventional real world practice which is frequently 8-N-1; 8 bits, N for no parity and 1 stop bit.

In the real world, 8-N-1 works better than 8-N-2 because a lot of devices no longer support 2 stop bits. Which parity is selected does not really matter as long as both devices use the same parity and word size. It's gotta match on both ends.

The Modbus spec says that Even parity must be implemented, but like the requirement of 2 stop bits for no parity, the requirement is frequently ignored.

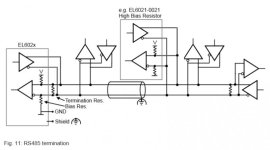

2) termination resistors

The cable used for 485 has an 'impedance' and the resistors are supposed to match the impedance of the cable. 120 ohm resistors are typically used for RS-485.

With 2 meters of cable at low baud rates, you'll probably never see a problem with reflected power, but it's recommended practice to put the terminating resistors in place.

3) Notice in your posted diagram that there's a 3rd wire, a signal ground. The concept of 2-wire RS-485 is a misnomer, a falsehood. RS-485 is supposed to have a signal ground.

The problem is poorly implemented RS-485 where the vendor does not provide a signal ground or uses the chassis ground. The use of a chassis ground can cause all sort of problems due to noise and common mode.

4) The mystery of RS-485 is biasing. The driver lines are supposed to be biased at one point, one line to 0V, the other line to +V.

Implementation of Profibus DP (RS-485) take this into account with connections that allow switching in biasing or termination as needed, but the rest of the world suffers in ignorance. Biasing is usually not even mentioned.