sayahan2003

Member

Hi my friend,

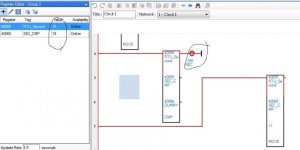

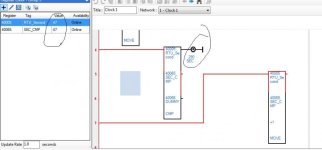

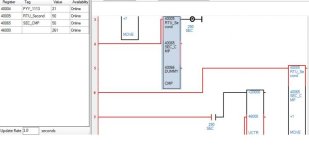

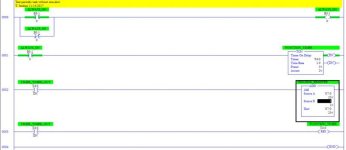

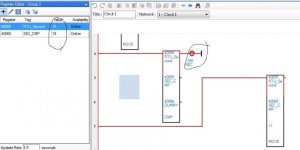

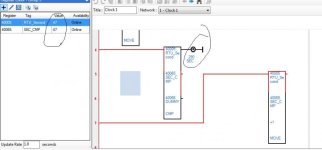

In the following network, can you tell me when the one-shot coil is on? The register 40005 is the "RTU second". as you see in first photo, both registers 40005 and 40065 are equal but the coil is on. in the second photo, both registers are still equal but the coil is not on. during one minute interval, sometimes the coil become on more than once. but sometimes only once and this will happen in various seconds not a specific second.

it is very confusing

Thanks in advance for your time.

In the following network, can you tell me when the one-shot coil is on? The register 40005 is the "RTU second". as you see in first photo, both registers 40005 and 40065 are equal but the coil is on. in the second photo, both registers are still equal but the coil is not on. during one minute interval, sometimes the coil become on more than once. but sometimes only once and this will happen in various seconds not a specific second.

it is very confusing

Thanks in advance for your time.