Similar Topics

In our water cooling tank, I've installed and successfully wired up 4 float switches & updated the PLC (big thanks to @parky for that).

As a...

I am trying to build a project for controlling water level in a tank using PLC,3 level sensor, water pump, and electrical valve and i need help...

Hello..

i need help doing my project..i dont know how to start using CJ1M plc..can anyone?

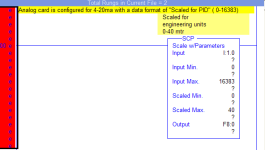

need to know how to determine how much water in a tank by taking the MA output of a transmitter and converting it to feet of H2O.

thanks

We've had an intermittent issue with this for years. The application is sensing a level, or more accurately the absence of level in smallish ~5-10...