I'm loading bulk tankers with dry powder using a 1769-L33ER. Product is fed through gates, and close to the end of the load the system jogs product to top off the tank. During this cycle, we open the gate for a few seconds and close the gate for a few seconds until the truck is full.

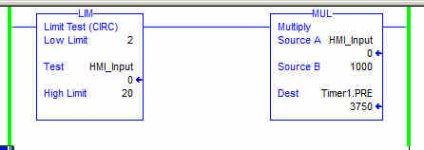

We labelled these parameters duration and interval, and operators have the ability to adjust them using numeric inputs in Factory talk to alter the presets of the timers that control this. The HMI input is multiplied by 1000 in Logix, and the destination for that instruction is the preset on the time that controls the activity.

Recently we've started faulting the processor, and what I'm finding is that the preset on one of these timers gets set to a negative number. I've set min/max on the HMI numeric inputs, so the operator shouldn't be able to enter a negative number. I'm scratching my head over this.

Has anyone ever seen this before, and what solutions did you come up with?

We labelled these parameters duration and interval, and operators have the ability to adjust them using numeric inputs in Factory talk to alter the presets of the timers that control this. The HMI input is multiplied by 1000 in Logix, and the destination for that instruction is the preset on the time that controls the activity.

Recently we've started faulting the processor, and what I'm finding is that the preset on one of these timers gets set to a negative number. I've set min/max on the HMI numeric inputs, so the operator shouldn't be able to enter a negative number. I'm scratching my head over this.

Has anyone ever seen this before, and what solutions did you come up with?