What I called Data Number or DN there, is often referred to as the "raw counts," or just "counts," value that an analog input module passes to the PLC.

An analog input module has channels, and each channel performs an "Analog to Digital Conversion;" such devices are often called A/D or ADC. The analog part is an incoming external signal that is usually electrical in nature, such as a a voltage or a current; the digital part is "raw counts" an integer that is passed to the PLC program input memory location, and binary value of some number of bits, which value is linear with the analog signal. In the example above, if the incoming analog electrical signal is 10V, then the digital counts value is 16383.

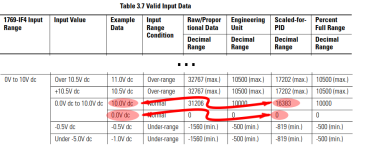

For a 16-bit module, the counts value is usually* in the range -32,768 to +32,767; for a 14-bit module, it might be in the range 0 to 16,383. For the exact

meaning of the value you need to refer to how the module itself and its configuration; in the example above I assumed it was similar to an Allen-Bradley 1769-IF4 or 1769-IF8 configured for 0-10VDC with [Scaled-for-PID] as the [Input Data Selection Format] cf.

here and below.

* also sometimes 0-65,535

View attachment 55320