Interesting idea on the polarity, Ron. I guess I'll ask a follow-up that will likely betray my ignorance: if an RTD were to be wired to the module incorrectly, could the value still show what appears to be a valid number, but the value would decrease as the temperature rises and increase as the temperature falls? Or is it possible that the physical RTD itself is faulty and causes an increase in ohms when it should decrease and vice versa?

In my experience with RTD's, if they are not wired correct they read an off scale, not an apparently "valid" temp.

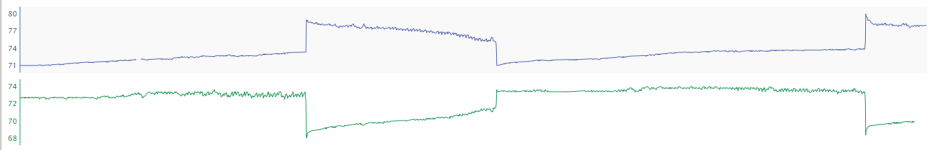

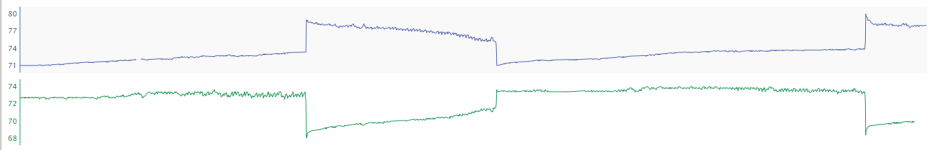

If you are suspecting some kind of issue with the software that shows the trends, I don't think that this is the issue but I will setup a live trend in RSLogix to see if the raw values in the block transfer data table match what the external trending software is showing.

Thanks to all for the suggestions!