buhnen

Member

Hi everybody,

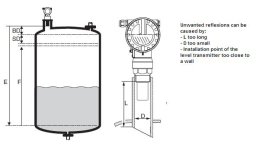

I need any hints for trying to solve a little prob here. I'm feeding an input channel of a 1769-IF8 analog module with a current based signal of 4-20 mA linked from a measuring field device, an ultrasonic level transmitter,a SIEMENS Sitrans Probe LU and I'm obtaining "jittering" input readings. If, for

instance, the admitted measuring range by the LIT is 300 centimetres and the real level for the water levelline in the tank is 100 metres, my input readings are waving in a range of 10 centimetres as I can monitor them on the RSLogix( 99, 105, 103, 110...like that, randomly). For the particular case of

my application, an inaccuracy of about 10 cmts is fairly acceptable, but still I wonder how to improve the quality for my signal.This is because afterwards I will program a routine for keeping the levelline steady at a certain setpoint (by means of a speedrive controlling a pumping out process)and this setpoint shouldn't go out of a range of 10 centimetres, (otherwise I'd have to start up secondarily another pump supporting the main one).

The field device seems to be correctly installed and programmed (no error messages displaying)...the fluid whose level I want to monitor (sewage waters) have no foams which might be disturbing the ultrasonic echoes of the LIT. And this "jittering" is happening when no flow is being drive to the tank inlet, this is, when the level is steady.

Any clue, tip, hint, strategy...?

Thanks in advance.

I need any hints for trying to solve a little prob here. I'm feeding an input channel of a 1769-IF8 analog module with a current based signal of 4-20 mA linked from a measuring field device, an ultrasonic level transmitter,a SIEMENS Sitrans Probe LU and I'm obtaining "jittering" input readings. If, for

instance, the admitted measuring range by the LIT is 300 centimetres and the real level for the water levelline in the tank is 100 metres, my input readings are waving in a range of 10 centimetres as I can monitor them on the RSLogix( 99, 105, 103, 110...like that, randomly). For the particular case of

my application, an inaccuracy of about 10 cmts is fairly acceptable, but still I wonder how to improve the quality for my signal.This is because afterwards I will program a routine for keeping the levelline steady at a certain setpoint (by means of a speedrive controlling a pumping out process)and this setpoint shouldn't go out of a range of 10 centimetres, (otherwise I'd have to start up secondarily another pump supporting the main one).

The field device seems to be correctly installed and programmed (no error messages displaying)...the fluid whose level I want to monitor (sewage waters) have no foams which might be disturbing the ultrasonic echoes of the LIT. And this "jittering" is happening when no flow is being drive to the tank inlet, this is, when the level is steady.

Any clue, tip, hint, strategy...?

Thanks in advance.