Hi Everyone,

I have bought a Temperature and Humidity Sensor combo and I'm not sure how to covert them to actual (C*) and (RH) unit.

I have connected it to my Micro820 and I get some readings from them using connected component software. But I'm not sure what these values mean. Like is it voltage difference or what??

I have attached the translated manual for the sensor

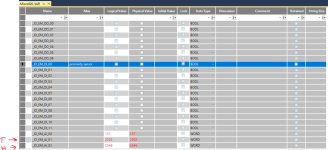

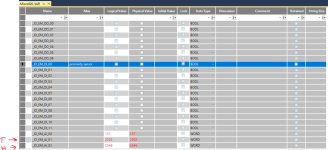

Image of Connected Component software showing each of the sensor's output values:

https://freeimage.host/i/HKvA929

Link to the sensor:

https://www.aliexpress.com/item/4001310289075.html?spm=a2g0o.productlist.main.39.2cb7604dzrx0iL&algo_pvid=e66a2da9-9204-42cf-a97c-eb7bd61c1e3a&algo_exp_id=e66a2da9-9204-42cf-a97c-eb7bd61c1e3a-19&pdp_ext_f=%7B%22sku_id%22%3A%2212000015584580815%22%7D&pdp_npi=2%40dis%21USD%2129.0%2125.23%21%21%21%21%21%4021227a0f16671968348543938d078c%2112000015584580815%21sea&curPageLogUid=Ef0Xf5smV6b3

I have bought a Temperature and Humidity Sensor combo and I'm not sure how to covert them to actual (C*) and (RH) unit.

I have connected it to my Micro820 and I get some readings from them using connected component software. But I'm not sure what these values mean. Like is it voltage difference or what??

I have attached the translated manual for the sensor

Image of Connected Component software showing each of the sensor's output values:

https://freeimage.host/i/HKvA929

Link to the sensor:

https://www.aliexpress.com/item/4001310289075.html?spm=a2g0o.productlist.main.39.2cb7604dzrx0iL&algo_pvid=e66a2da9-9204-42cf-a97c-eb7bd61c1e3a&algo_exp_id=e66a2da9-9204-42cf-a97c-eb7bd61c1e3a-19&pdp_ext_f=%7B%22sku_id%22%3A%2212000015584580815%22%7D&pdp_npi=2%40dis%21USD%2129.0%2125.23%21%21%21%21%21%4021227a0f16671968348543938d078c%2112000015584580815%21sea&curPageLogUid=Ef0Xf5smV6b3