Good Day everyone

I am currently writing a program for a 4 cylinder press i have it mostly done.

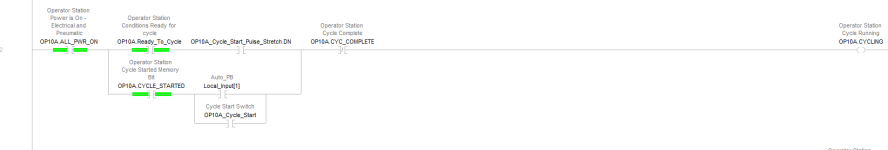

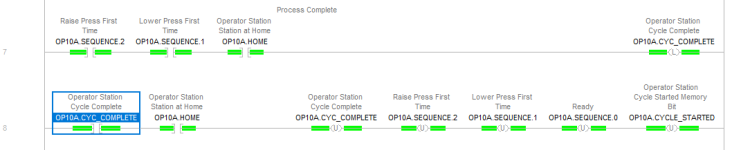

just have one issue with my program where i put it in auto and i flick the switch for it to start its cycle. the 4 cylinder press just goes down for 2.5 sec then comes back up to home postion and then goes back down and keeps doing this till i put it in manual or press the e stop.

what is suppose to happen is that once it goes down for the 2.5 sec and comes back to home that should end the cycle or be its full cycle till i flick the switch again for it to then start its cycle again.

im not sure what i am missing maybe for the plc to tell it to stay home till i do flick the switch again to start its cycle but as of now it just keeps looping in cycle as i can see it and cant find where it can stay home and end its cycle.

there are only 4 sensors on this press which are home sensors.

i will attached the project file or maybe attached screen shots to have a better look. the main logic is in the cycle sequence and press logic under OP10A

I am currently writing a program for a 4 cylinder press i have it mostly done.

just have one issue with my program where i put it in auto and i flick the switch for it to start its cycle. the 4 cylinder press just goes down for 2.5 sec then comes back up to home postion and then goes back down and keeps doing this till i put it in manual or press the e stop.

what is suppose to happen is that once it goes down for the 2.5 sec and comes back to home that should end the cycle or be its full cycle till i flick the switch again for it to then start its cycle again.

im not sure what i am missing maybe for the plc to tell it to stay home till i do flick the switch again to start its cycle but as of now it just keeps looping in cycle as i can see it and cant find where it can stay home and end its cycle.

there are only 4 sensors on this press which are home sensors.

i will attached the project file or maybe attached screen shots to have a better look. the main logic is in the cycle sequence and press logic under OP10A