Dear,

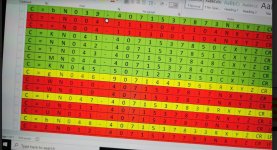

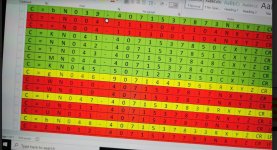

Xray machine is communicating with the PLC using RS422communication, some of the addresses are being read by the PLC, other addressesare not read, when we checked the pattern of the sent addresses using a scanneron the XRAY machine, it was noticed that some addresses are being repeatedon a later stages, please refer to attached, so ID's 41, 42, 43, 44 and 45 (C=K is check sum, ID startsafter the letter N) are properly read by the PLC however, ID 46 in yellow isnot read by the PLC since it is followed by repeated old ID's (ID-10), any ideawhy old ID's are being repeated?

is this a communication issue, echo is happening?

any thought on this subject are really appreciated

Xray machine is communicating with the PLC using RS422communication, some of the addresses are being read by the PLC, other addressesare not read, when we checked the pattern of the sent addresses using a scanneron the XRAY machine, it was noticed that some addresses are being repeatedon a later stages, please refer to attached, so ID's 41, 42, 43, 44 and 45 (C=K is check sum, ID startsafter the letter N) are properly read by the PLC however, ID 46 in yellow isnot read by the PLC since it is followed by repeated old ID's (ID-10), any ideawhy old ID's are being repeated?

is this a communication issue, echo is happening?

any thought on this subject are really appreciated