No, E-stop buttons are N/C by default so when not operated they are closed.

The idea of an E-stop is it breaks the contact so in the logic a normally open contact (PLC wise) would reset the pump run bit which is not what you want.

So a N/C will be off if the input is on. Pressing the E-stop will drop the power to the input thus the N/C contact in the PLC will be false or made.

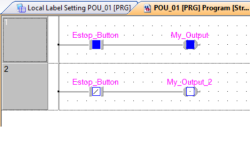

See pic.

On the first rung the e-stop is on (default not pressed) so the result of logical operation is true as can be seen on the output i.e. it turns it on

The second rung shows the N/C contact i.e. the input is true but because the contact is N/C the result of logical operation is false so the output is off

if these outputs were reset operation the N/C contact when the e-stop operated would reset the output, I wonder how many people have made this mistake before changing the N/O to N/C lol.

Edit:

Perhaps I should explain my reasoning behind the E-stop.

Any equipment that could be seen as a possible danger if failed should have a way of quickly rendering the equipment safe, it is common on a plant to have strategically placed emergency stop buttons that render the equipment safe i.e. stop the plant instantly (or if required a safe quick stop). Most machines or plant will have at least one of these the idea is that it will remove the potential that drives some form of mechanical operation.

Depending on the safety category will have a guided safety control unit that removes the potential's on the control equipment. For continued safety is it common not only to remove the potential on the equipment but also feed the status to a controller, so if someone presses an e-stop the potential is removed from the controlling device (example a contactor driving a motor) it also resets the program output so on release or re-energisation of the e-stop the plant does not automatically start back up suddenly i.e. there is operator intervention to re-start the system. There are of course many aspects of what is safe to do and what is not.

Take an example of a machine where the operator opens a guard, this then removes potential to the motor drives, the operator goes inside, the door closes behind him, if the guard system automatically re-energised then that person could be in danger, therefore, it makes sense not to have automatic reset but a deliberate re-start by the operator. Ideally a person entering should lock off any form of restart to stop others from re-starting the plant. Any remote equipment should have local isolation & a notice stating it may re-start without warning Any modifications you intend to do need to be risk assessed to ensure plant safety.