naturally there's more to this story ...

my advice is that you do NOT remove or otherwise alter the "weird" rung that's causing so much confusion ... here's why ...

everything that's been posted so far is assuming that the system will always be used in "normal day-to-day" operation ...

but ...

the original programmer was apparently making use of the Allen-Bradley "PRESCAN" operation to handle certain "Go-To-Run" situations ... (including a possible power failure - and a subsequent return of the power) ...

here's how to get a better understanding of what you're looking at ...

suppose that we enter a new temporary "test" rung and then go through a few experiments ... (WARNING! ... naturally it would be safest to do this with a lab setup – rather than with the company's production equipment) ...

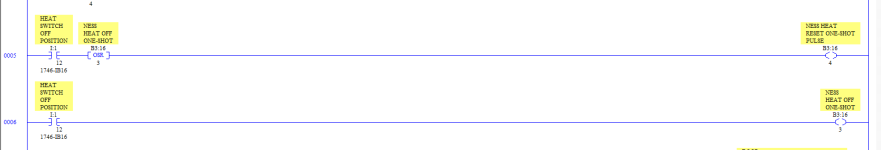

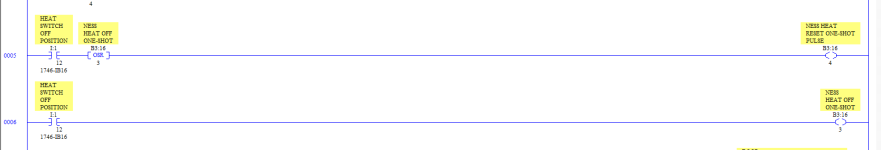

the "test" rung should be located BELOW the two rungs that you've already posted ...

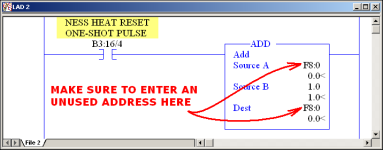

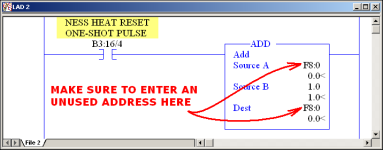

the new test rung should consist of an XIC instruction – with the address B3:16/4 – which is the bit address documented as "NESS HEAT RESET ONE-SHOT PULSE" in your existing code ...

the rung should also include an ADD instruction ... resist the temptation to use a CTU (Counter) instruction instead ... you'll get much more reliable results from the test by using a simple ADD instruction ... for Source A – and for the Destination entries of the ADD instruction – use a previously UNUSED Float location ... I'm using F8:0 for my example – but MAKE SURE that the address that you enter has NOT been used elsewhere in your entire code ... for Source B of the ADD instruction just enter the value of 1 ...

now to execute the experiment ...

as you flip the field input back and forth – your input signal I:1/12 (documented as HEAT SWITCH OFF POSITION) should cycle between "green on the screen" – and NOT "green on the screen" ... and the value shown at the Destination of your ADD instruction should INCREMENT by 1 each time the switch's XIC instruction highlights as green ...

this indicates "normal" day-to-day operation of the code that you posted ... in simple terms, the OSR is "firing" for one scan each time the field input passes electrical current ... this is what has been discussed so far in your thread ...

now let's go deeper ...

leave your field input signal I:1/12 in whatever position you need to give you a "green on the screen" highlight ... now cycle the SLC processor several times between the Program mode and the Run mode ... you can do this either with the keyswitch – or remotely by using the keyboard of your computer ... you should see the value shown at the Destination of your ADD instruction INCREMENT by 1 each time the processor goes into the Run mode ...

now let's go even deeper ...

completely remove (DELETE) the rung shown as Rung number 0006 in your original post ... specifically, get that "confusing" rung completely OUT of your code ... do NOT simply "disable" the rung in any way ... you can reinsert the rung once the testing is finished ...

now here's the kicker ...

once again - leave your field input signal I:1/12 in whatever position you need to give you a "green on the screen" highlight ... now again - cycle the SLC processor several times between the Program mode and the Run mode ...

this time, the value shown at the Destination of your ADD instruction will NOT increment each time the processor goes into the Run mode ...

ding – ding – ding ...

note that the results of a "Go-To-Run" event will be DIFFERENT once the "confusing" rung has been removed ...

so ...

I'd be willing to bet some SERIOUS money that your original programmer was making use of Allen-Bradley's little-known PRESCAN feature to insure that whatever "stuff" is being controlled by that B3:16/4 bit (NESS HEAT RESET ONE-SHOT PULSE) in OTHER places in your existing code – actually gets executed whenever the processor first goes into the Run mode – without having to manually recycle the field input device for bit I:1/12 ...

TIP: there are different – and probably better – ways to achieve the same results – and frankly I think that the original programmer should have included more documentation about what he was trying to accomplish ...

hope this helps ... party on ...

.