I know that putting coils in series instead of branches and starting a rung with the less likely condition to be true has a good effect on scan time.

What other tips and tricks that will improve the scan time?

Thanks for sharing your knowledge

1. Move code that doesn't need to be scanned at a fast rate to periodic tasks. (as cardosocea suggested). It is not required that the application has a continuous task at all, everything can be programmed into periodic and event tasks.

2. Don't continuously scan program code when it is not needed, e.g. the sequencing logic for a step-sequencer need only be scanned if the sequence is active. I have worked extensively on plant that has "Process" sequences, and CIP or IPC (Cleaning-In-Place or In-Place-Cleaning) sequences. Often these are mutually exclusive, so they don't need to be scanned at the same time.

3. Input branching - place the branch most likely to be

true as the top branch. This has a marginal effect, as the lower branches still need to be scanned, in case there are any output instructions on them.

4. Avoid using instructions with a "Control" tag (i.e. Timers, Counters, FALs etc. These have to be 'executed' even though the rung may be false. If you can find another way to do the logic you need, it will most likely be faster.

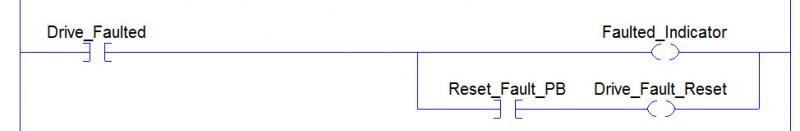

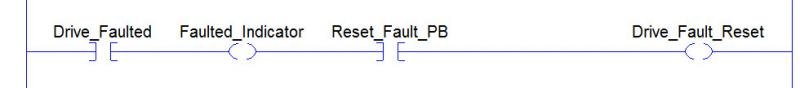

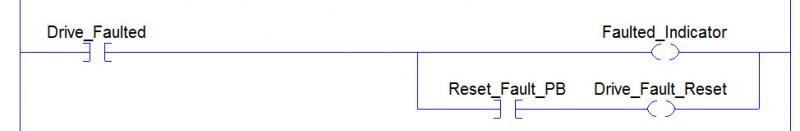

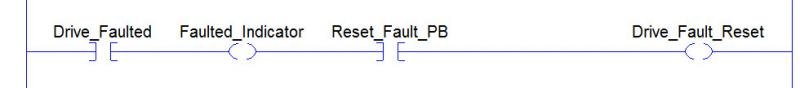

5. You can mix conditional and output instructions anywhere on the rung. Compare Picture1 and Picture2 - they both perform exactly the same function, but Picture2 will execute faster, and has 2 fewer instructions (Picture1 has 6, Picture2 has 4), that's a 33% saving just on one rung !!

For the uninitiated, the two "tricks" tarik1978 quoted have the following reasoning....

1. "Coils in series" - you are using less instructions in the code. The ladder representation only hints at the fact that the branches are actual instructions that the controller has to scan - such as BST (Branch Start), BND (Branch End), NXB (next Branch. Reducing the number of instructions by not using branches not only speeds up the execution, but also reduces memory consumption.

2. "Least Likely to be true".... - once a rung is evaluated as "false", it cannot be turned true again (until a BND or NXB is encountered), so execution of further conditional instructions does not require the controller to read the states or values of the associated tags of the following instructions, and simply "passes them by" as quickly as possible.