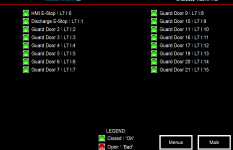

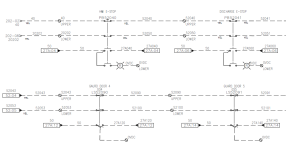

In my current place of work, some of our lines have a lot of E-Stops and safety devices scattered around and if one of them acts up or we have a wiring issue, it's a real pain in rear to find the culprit. I'm assuming that there are accepted methods/devices out there that will allow you to see the state of these devices individually so that you have a place to start when troubleshooting and if so i would appreciate a nudge in the right direction. We use Allen Bradley control products.

Components that allow you to see the state of individual EStops, Safteys, etc..

- Thread starter jds8086

- Start date

Similar Topics

Hello everyone,

I am working in a platform and we installed FTV CLIENT SE V 12 IN ALL THE CLIENTS COMPUTERS, we have 6 clients and only 1 is not...

Hello everyone,

I'm having issues with connected components. I got a new laptop and I installed all the RA programs I need without problem. I was...

Connected Components Help

Hi there everyone,

I’m recently new to the PLC world and was hoping somebody might steer me in the right...

was trying to use Connected Components to connect to a 525 drive via usb with the face off but can't seem to connect to it. the screen lights up...

So I'm using CCW to program a panel view and this is not my first I have done many. My Problem is I get an error message that I have never seen...