Mas01

Member

Hi,

Our PLC measures WATER FLOW RATE as an analog input.

The PLC reads it as an integer value (D34) in the range 0-4000 as follows:

Range: 0-100 m3/hr

Current: 4-20mA

Linear relationship:

4mA= 0 m3/hr (PLC value 0000)

12mA= 50 m3/hr (PLC value 2000)

20mA= 100 m3/hr (PLC value 4000)

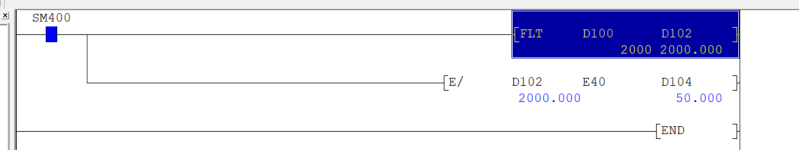

The conversion is as follows:

Flow Rate = [ (PLC value/200,000) * 6250] -25

What's the best way to do this conversion? In the ladder logic or "linked" to the "script" in the GUI?

The data analysis person has asked for the exported data (csv file) to be shown in engineering units, not the raw value.

At the moment he gets the raw value and has to do the conversion himself, but prefers engineering units

Can the PLC (Q-series) handle the division without losing too much accuracy?

Should the conversion be done in the ladder logic? Is that the best place to do it? Thanks

Our PLC measures WATER FLOW RATE as an analog input.

The PLC reads it as an integer value (D34) in the range 0-4000 as follows:

Range: 0-100 m3/hr

Current: 4-20mA

Linear relationship:

4mA= 0 m3/hr (PLC value 0000)

12mA= 50 m3/hr (PLC value 2000)

20mA= 100 m3/hr (PLC value 4000)

The conversion is as follows:

Flow Rate = [ (PLC value/200,000) * 6250] -25

What's the best way to do this conversion? In the ladder logic or "linked" to the "script" in the GUI?

The data analysis person has asked for the exported data (csv file) to be shown in engineering units, not the raw value.

At the moment he gets the raw value and has to do the conversion himself, but prefers engineering units

Can the PLC (Q-series) handle the division without losing too much accuracy?

Should the conversion be done in the ladder logic? Is that the best place to do it? Thanks

Last edited: