gbradley

Lifetime Supporting Member

Does anyone know where to find the Fault codes for SLC?

We recently moved a 150 HP Motor about 20 feet from where it was previously.

Nothing has changed in the Ladder file, however, the Processor has faulted three times, since.

I have had to re-download the program to the PLC in order to fix the problem.

It seems to fault when the motor is started.

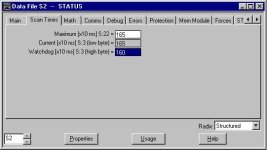

Fault 002h

Unexpected hardware watchdog timeout or an ASIC reset occurred.

My theory is that the voltage drop when the motor is started is too much for the PLC?

I measured the incoming voltage and it is about 124 Volts, and it drops to about 118 Volts when the motor is started.

This doesn't seem to be too much to me???

I am going to wrap the incoming AC power to the PLC around a toroidal inductor to see if this helps.

Any suggestions??

We recently moved a 150 HP Motor about 20 feet from where it was previously.

Nothing has changed in the Ladder file, however, the Processor has faulted three times, since.

I have had to re-download the program to the PLC in order to fix the problem.

It seems to fault when the motor is started.

Fault 002h

Unexpected hardware watchdog timeout or an ASIC reset occurred.

My theory is that the voltage drop when the motor is started is too much for the PLC?

I measured the incoming voltage and it is about 124 Volts, and it drops to about 118 Volts when the motor is started.

This doesn't seem to be too much to me???

I am going to wrap the incoming AC power to the PLC around a toroidal inductor to see if this helps.

Any suggestions??