Ron Beaufort

Lifetime Supporting Member

Greetings to all ...

I had an exceptionally bright and highly motivated student in one of my ControlLogix PID classes the other day ... this guy was absolutely determined to "boldly go" where others had never been ...

some of the things that he was particularly interested in were the following settings for the 1756-IF8 analog input modules that we normally use for the Hotrod loop tuning experiments ...

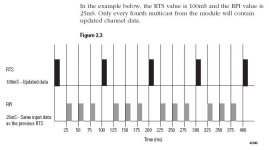

(a) the RPI (Requested Packet Interval) setting ...

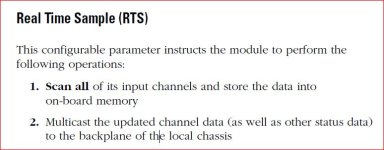

(b) the RTS (Real Time Sample Period) setting ...

(c) the Module Filter setting ... and ...

(d) the Digital Filter setting ...

all of these were important to him since he was personally involved in an on-going project back at his plant – and getting as fast a response as possible from the PID was considered a major objective of the project ...

anyway ...

I was able to pull together a few demonstrations in the lab which helped us work through our most pressing concerns ... since then, I've cleaned up SOME (but definitely not ALL) of the rough edges ... at some point in the future I might nail all of these down into some sort of "lesson" – but for now I thought that my preliminary notes might possibly be of interest to the forum ... note: this is probably overkill for most people – since I don't recall that the topic has ever come up for discussion before ... but I offer it for what it's worth ...

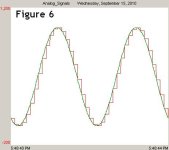

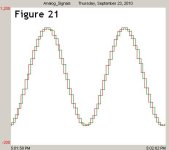

the basic idea for the experiments was to connect TWO 1756-IF8 analog input modules in parallel with each other – so that each module would sample exactly the same voltage input signal ... the analog output signal was provided by a 1756-OF4 analog output module ... I kludged together (no other term for it) a method of injecting a certain amount of artificial "noise" into the output signal by chattering a separate relay output (details available upon request) ...

so ...

by trending the various signals I've been able to come up with a series of graphs which answer all of my personal requirements about this topic ... if you're interested in this project, I suggest the following game plan:

(1) print out the RPI_RTS_Spreadsheet.PDF file which shows the setups for the various tests that I ran ...

(2) right-click the 01.PNG picture file and select "Preview" from the Windows pop-up menu ... then use the right and left arrow keys on your keyboard to do a simple "slide show" and cycle through the figures ...

you might also want to open the RPI_RTS_Figures.DOC file which shows the various graphs all in a series ... I recommend that you view this file at 150% zoom size for best results ...

if anyone has any questions, I'll be happy to try to answer them – but right now I'm tied up in other some rather pressing projects – so it might be awhile before I'll have time to nail things down ...

party on ...

I had an exceptionally bright and highly motivated student in one of my ControlLogix PID classes the other day ... this guy was absolutely determined to "boldly go" where others had never been ...

some of the things that he was particularly interested in were the following settings for the 1756-IF8 analog input modules that we normally use for the Hotrod loop tuning experiments ...

(a) the RPI (Requested Packet Interval) setting ...

(b) the RTS (Real Time Sample Period) setting ...

(c) the Module Filter setting ... and ...

(d) the Digital Filter setting ...

all of these were important to him since he was personally involved in an on-going project back at his plant – and getting as fast a response as possible from the PID was considered a major objective of the project ...

anyway ...

I was able to pull together a few demonstrations in the lab which helped us work through our most pressing concerns ... since then, I've cleaned up SOME (but definitely not ALL) of the rough edges ... at some point in the future I might nail all of these down into some sort of "lesson" – but for now I thought that my preliminary notes might possibly be of interest to the forum ... note: this is probably overkill for most people – since I don't recall that the topic has ever come up for discussion before ... but I offer it for what it's worth ...

the basic idea for the experiments was to connect TWO 1756-IF8 analog input modules in parallel with each other – so that each module would sample exactly the same voltage input signal ... the analog output signal was provided by a 1756-OF4 analog output module ... I kludged together (no other term for it) a method of injecting a certain amount of artificial "noise" into the output signal by chattering a separate relay output (details available upon request) ...

so ...

by trending the various signals I've been able to come up with a series of graphs which answer all of my personal requirements about this topic ... if you're interested in this project, I suggest the following game plan:

(1) print out the RPI_RTS_Spreadsheet.PDF file which shows the setups for the various tests that I ran ...

(2) right-click the 01.PNG picture file and select "Preview" from the Windows pop-up menu ... then use the right and left arrow keys on your keyboard to do a simple "slide show" and cycle through the figures ...

you might also want to open the RPI_RTS_Figures.DOC file which shows the various graphs all in a series ... I recommend that you view this file at 150% zoom size for best results ...

if anyone has any questions, I'll be happy to try to answer them – but right now I'm tied up in other some rather pressing projects – so it might be awhile before I'll have time to nail things down ...

party on ...

Last edited: