You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Allen-Bradley Micro810

- Thread starter ceilingwalker

- Start date

MechatronicsMan

Member

Ken Roach

Lifetime Supporting Member + Moderator

Automation high-five !

MechatronicsMan

Member

Automation Group Hug!!

(8{)} ( .)

Lifetime Supporting Member

This software looks suspiciously like CoDeSys v3. Am I mistaken?

(8{)} .)

.)

(Yosi)

(8{)}

(Yosi)

MechatronicsMan

Member

Hi Yosi

Not sure, I've never used Codesys

Not sure, I've never used Codesys

Ken Roach

Lifetime Supporting Member + Moderator

The Allen-Bradley Micro 800 series editor is built into a package called "Connected Components Workbench", or "CCW" that also launches configuration programs for the PanelView Component and the small Kinetix drives.

Under the hood, the controller is running ISaGRAF and PLCOpen Motion routines, and the editor is done in Microsoft Visual Studio.

The good news about CCW is that there's plenty of room for future improvement.

Under the hood, the controller is running ISaGRAF and PLCOpen Motion routines, and the editor is done in Microsoft Visual Studio.

The good news about CCW is that there's plenty of room for future improvement.

ceilingwalker

Lifetime Supporting Member

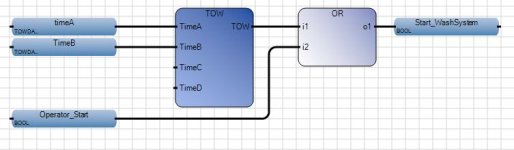

The hardest thing about this is learning how the TOW instruction doesn't have named instances, and uses instruction-specific time value structures named TOWDATA.

As you've stated the application, you can do this in three rungs:

Thank you. Mine looks the same except I had to add an "R_Trig" as sort of a one-shot for my push button. I'm just enjoying the fact that mine was the same as yours Ken. You being a seasoned veteran and all. Always appreciate yours and everyone heres' help. Thanks again.

ceilingwalker

Lifetime Supporting Member

Hi Ceiling walker

I've attached a picture of what I Meant earlier.

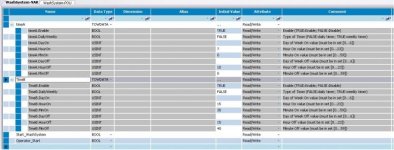

once you have the TOW block in the middle of your screen grab the Variable block from the left and drag it on to your screen as well. Then double click on the variable block you just dragged and it will take you to the variables that have been created already, if there aren't any you can create them as you go. Create TimeA and TimeB. they need to be data type TOWDATA. then fill in the details. I've attached a picture of the variables and the blocks the way you described your process

Thanks much. I always learn more here than at the manufacturer's site.

ceilingwalker

Lifetime Supporting Member

I do have a wiring question, please. I wanted 24VDC out to my push buttons so I have the "-" of the power supply connected to the "NC" terminal position and the "+" to the "I-00" terminal position. They are each connected to one side of the push button. I was expecting to see the input make and break, but nothing. Looking at the wiring diagram it appears that I have it wired correctly but nothing. Thank you

"NC" on terminal strips usually mean "Not connected". Post the model plc and I will look at the terminations in the manual.I do have a wiring question, please. I wanted 24VDC out to my push buttons so I have the "-" of the power supply connected to the "NC" terminal position and the "+" to the "I-00" terminal position. They are each connected to one side of the push button. I was expecting to see the input make and break, but nothing. Looking at the wiring diagram it appears that I have it wired correctly but nothing. Thank you

Page 10 in this manual in the link below, show some different layouts.

The only layout I see with the "NC" terminal is for the is for the 2080-LC10-12AWA. That model uses 120 to 240 VAC for the inputs, not 24VDC. Depending on the model, you may also have to jumper terminals 2 to 3 on the input strip if they are not already jumpered internally.

Link:

http://literature.rockwellautomation.com/idc/groups/literature/documents/in/2080-in006_-en-p.pdf

Last edited:

ceilingwalker

Lifetime Supporting Member

"NC" on terminal strips usually mean "Not connected". Post the model plc and I will look at the terminations in the manual.

Page 10 in this manual:

http://literature.rockwellautomation.com/idc/groups/literature/documents/in/2080-in006_-en-p.pdf

Shows some different layouts.

The only layout I see with the "NC" terminal is for the is for the 2080-LC10-12AWA. That model uses 120 to 240 VAC for the inputs, not 24VDC.

Hopefully my attachment makes it here. This is what I was using.

ceilingwalker

Lifetime Supporting Member

Forgot to zip it. Here is the diagram I was using. Thanks again.

Looking at the attached zip file that typical drawing appears to show a Com terminal that must be connected to the "0" or - side of the power supply. Then, one side of your pushbutton contact connects to the + 24v side of the input power supply thru a fuse. Next, the other side of the pushbutton contact connects to the Input or I/P.

I'm looking back thru the thread and I see you are using the 2080-LC10-12AWA. I think this might be the manual you are using. See the terminals layouts starting on page 21.

Link:

http://literature.rockwellautomation.com/idc/groups/literature/documents/um/2080-um001_-en-e.pdf

P.S.

Go back and re-read my post #26. I made some edits.

I'm looking back thru the thread and I see you are using the 2080-LC10-12AWA. I think this might be the manual you are using. See the terminals layouts starting on page 21.

Link:

http://literature.rockwellautomation.com/idc/groups/literature/documents/um/2080-um001_-en-e.pdf

P.S.

Go back and re-read my post #26. I made some edits.

Last edited:

ceilingwalker

Lifetime Supporting Member

Turns-out the module I purchased I can not use 24VDC, only 120VAC. The literature was a little confusing because I did not read anywhere that my model wouldn't support that voltage input.

Similar Topics

Hello, Does anyone here have experience working with the a-b micro810 with the lcd display. We have churned out a workable program but the inbuilt...

- Replies

- 0

- Views

- 2,467

So I have just picked up one of these Micro810's and I am trying to program it to get a feel for the software. It's much different than RSLogix...

- Replies

- 0

- Views

- 4,385

Hi, I have a ControlLogix system with 1756-IF16 analogue inputs. I can't scale the inputs at the card as there is a requirement to facilitate...

- Replies

- 14

- Views

- 359

Dear community,

I am trying to find a tool for Allen-Bradley PLCs similar to SiVArch for Siemens PLCs to automatically generate faceplates and...

- Replies

- 0

- Views

- 92

Hi everyone, new to forum. Since very long time i having issue with 1734-AENT module, after some period of time its keep stuck in error (simmilar...

- Replies

- 16

- Views

- 607