Ali Sayghe

Member

Hi all

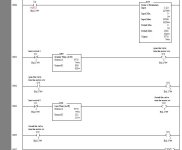

I am trying write a program that has analog input from a pressure sensor in a thank that read the pressure sensor for low level and high level when the pump start filling up the tank the motor for gate valve is closed when the water reach the high level the motor for the gate valve will open so the input and the output is:

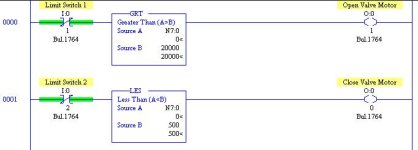

input I:0/1 from limit switch 1 to turn off the motor when its opening the valve

input I:0/2 from limit switch 2 to turn off the motor when its closing the valve

input I:2/1 analog input from pressure sensor

turn output O/0 when the signal from pressure sensor is low (111)

turn output O/1 when the signal from presser sensor is high (25000)

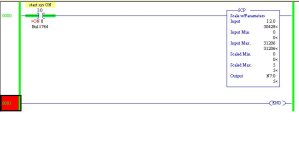

I have a 1769-IF8 Analog Input Card in a Micrologix 1500 system.

I am trying write a program that has analog input from a pressure sensor in a thank that read the pressure sensor for low level and high level when the pump start filling up the tank the motor for gate valve is closed when the water reach the high level the motor for the gate valve will open so the input and the output is:

input I:0/1 from limit switch 1 to turn off the motor when its opening the valve

input I:0/2 from limit switch 2 to turn off the motor when its closing the valve

input I:2/1 analog input from pressure sensor

turn output O/0 when the signal from pressure sensor is low (111)

turn output O/1 when the signal from presser sensor is high (25000)

I have a 1769-IF8 Analog Input Card in a Micrologix 1500 system.